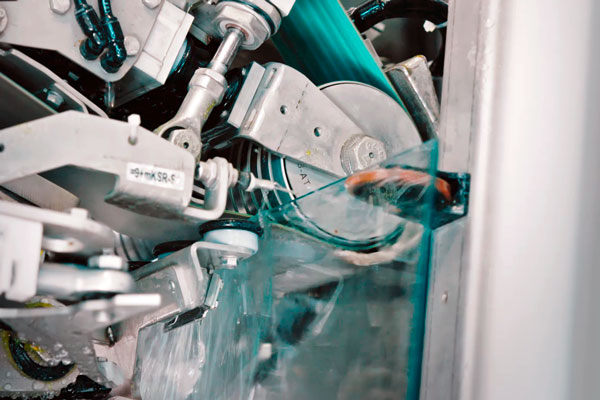

Edge seaming system length measuring

Consistently good seam quality depends significantly on the precision of the glass edge detection, which is also responsible for determining the sheet length.

You can clearly see the effect of imprecise edge detection in our example:

Just thousands of a second of delay or imprecision in the measurement result means up to a millimetre of imprecision in measurement at high machine processing speed, which has a direct effect on the quality of the resulting seam.

Exactly these sensors have been able to be improved for the new LiSEC machines in recent years. We offer you modification for retrofitting older LiSEC machines. With just a little effort, a marked improvement to the complete production chain can be achieved.

The new sensor features a significantly low maintenance cost than the previous mechanical solution, since the sensor that is now used is programmable and no additional adjustment by service personnel is required. The modification also promises an increase to the reaction speed of the sensors.

The modification can be completed within a day, and remote access to the system is needed for this. After completing the work, test run with a defined glass sheet is still needed to optimise the parameters.

Advantages:

- Improved results for the seam edge

- Increased productivity in downstream processes thanks to more consistent quality (e.g. tempering oven)

- Higher tool life of grinding belts

- No additional maintenance work on the sensor

Scope of services:

- Console including a new sensor

- Noise production hood to reduce noise load

- Inspection and optimisation of the machine parameters for length measuring

After making an enquiry, you will quickly receive a detailed offer including itemised costs that is specified for you especially.

Consistently good seam quality depends significantly on the precision of the glass edge detection, which is also responsible for determining the sheet length.

You can clearly see the effect of imprecise edge detection in our example:

Just thousands of a second of delay or imprecision in the measurement result means up to a millimetre of imprecision in measurement at high machine processing speed, which has a direct effect on the quality of the resulting seam.

Exactly these sensors have been able to be improved for the new LiSEC machines in recent years. We offer you modification for retrofitting older LiSEC machines. With just a little effort, a marked improvement to the complete production chain can be achieved.

The new sensor features a significantly low maintenance cost than the previous mechanical solution, since the sensor that is now used is programmable and no additional adjustment by service personnel is required. The modification also promises an increase to the reaction speed of the sensors.

The modification can be completed within a day, and remote access to the system is needed for this. After completing the work, test run with a defined glass sheet is still needed to optimise the parameters.

Advantages:

- Improved results for the seam edge

- Increased productivity in downstream processes thanks to more consistent quality (e.g. tempering oven)

- Higher tool life of grinding belts

- No additional maintenance work on the sensor

Scope of services:

- Console including a new sensor

- Noise production hood to reduce noise load

- Inspection and optimisation of the machine parameters for length measuring

After making an enquiry, you will quickly receive a detailed offer including itemised costs that is specified for you especially.

Contact me

Contact me