Systems & Lines

Laminated Glass Line

- LiSEC

- Systems & Lines

- Laminated Glass Line

- MaxLam

MaxLam

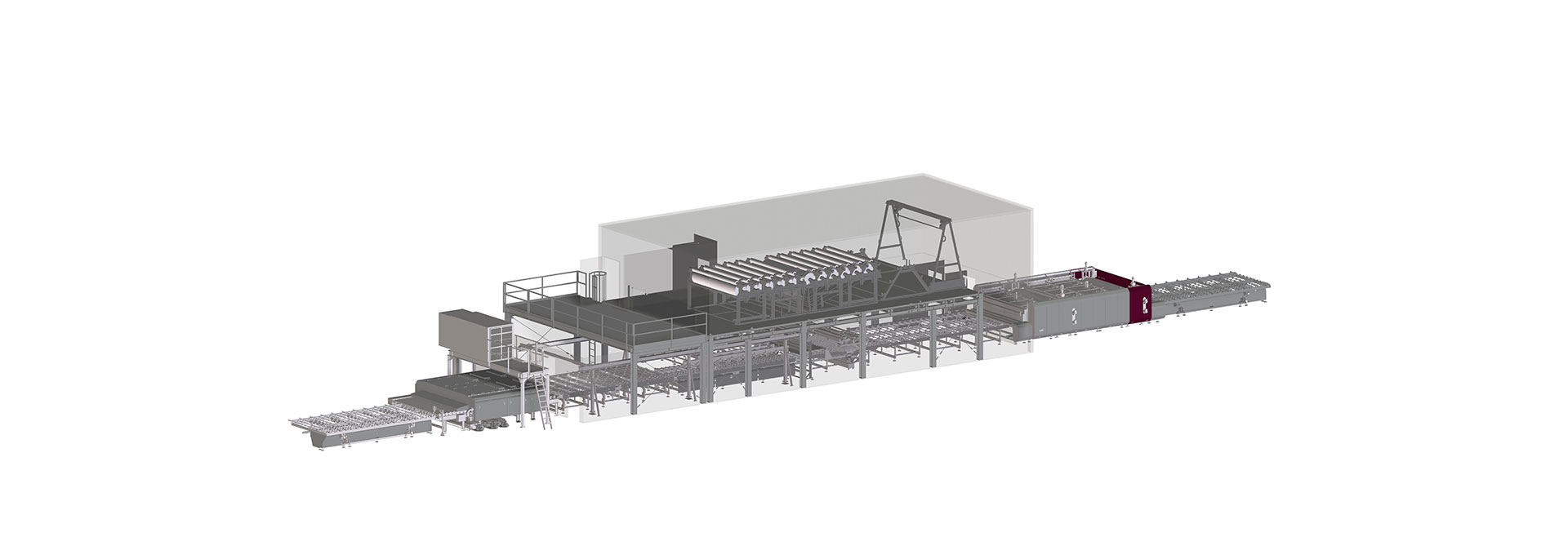

The two storey LiSEC Lamination Line with 12, 18 or 24 foil-rolls magazines for production halls with a minimum height of 6700 mm

The LiSEC MaxLam is a highly developed laminated glass line equipped with advanced laminating technology and precise machinery. Thanks to a high-pressure autoclave, the MaxLam is the perfect choice for producing all standard laminated and laminated safety glass products. This intelligent, tailored laminating system for PVB and SGP foils has two levels and can be equipped with 12, 18 or 24 foil roll magazines.

In this design, the LiSEC MaxLam requires a height of 6,500 mm. With the LiSEC PlusLam, a solution requiring less space is also available.*

The maximum production sizes (length x width) are:

- 12,000 x 3300 mm

- 9000 x 3300 mm

- 6000 x 3300 mm

- 6000 x 2800 mm

- 5000 x 2600 mm

- 4000 x 2000 mm

*Internal cleanroom height (+ 100 mm cleanroom ceiling height + >100 mm distance to the hall roof)

Like the LiSEC PlusLam, this line is available in the following equipment variants:

COMPACT - the most cost-effective type of pre-lamination for low production volumes of laminated glass.

COMFORT - a convenient and ergonomic high-speed, semi-automatic laminating system for customers with a wide variety of products and a large number of shapes. The line is designed for medium to high production volumes.

PREMIUM - an almost fully automatic, ergonomic and rapid laminating system designed especially for large production volumes of rectangular laminating glass.

In this variant, the focus is on aspects such as production cost optimisation.

Customised adaptations are possible.

All lines are equipped with a LiSEC pre-nip machine, with three different types to choose from:

- PNM-A (Double-Nip): for unit thicknesses up to 100 mm

- PNM-B (Double-Nip): for unit thicknesses up to 80 mm, up to 100 mm on request

- PNM-B (Single-Nip): can produce laminated safety glass up to 60 mm, greater glass thicknesses on request

The different variants have spindle press technology, which ensures precise and parallel pressing. Three heating systems are also available: Convection, radiation and a combination of both. The specially developed IR heaters enable rapid heating and switching on and off based on demand. The Eco-Heater function divides the heating zones into two segments to reduce energy consumption. The automatic speed adjustment also helps to save energy instead of opening flaps for cooling.

The servo spindle presses, the combination of the three heating methods, the automatic glass positioning, the automatic glass transfer and the electrical unwinding and rewinding of the foil are included as standard from the COMPACT equipment variant upwards. If desired, further options such as automatic cutting of the foil to the required length, automatic foil placement and the removal of excess foil can be individually selected.

How is the MaxLam laminating glass line configured?

The LiSEC MaxLam consists of three areas:

- A loading and washing area

- An assembly area

- A pre-lamination oven with downstream unloading area

Who is the MaxLam line suitable for in the production of laminated glass?

The LiSEC MaxLam line is suitable for all laminated glass manufacturers who wish to keep 12 to 24 rolls of foil in stock in the magazine and have a sufficient room height of > 6,500 mm. By choosing the right equipment variant, we can cater to individual customer needs. The line is characterised by a solid and durable design on which high-quality laminated safety glass can be produced. The servo spindle press, the ultra-modern heating method and the combination of convection and radiation make even complex structures a success. Thanks to this standard equipment, it is possible to manufacture everything from simple double LSG glass lites sheets to multi-laminates, such as walk-on, drive-on, bullet-proof glass and even glass fins as static units. Thermal insulation coatings and highly reflective solar control coatings can also be processed with it. The more air there is between the intermediate layers, the more advantageous it is to displace this in advance with the first roller press, before the edge seal is sealed with the second roller press. This opens up an even wider field of activity, new sales opportunities and high added value for the processor.

Which functions are standard?

- Three different equipment lines: COMPACT, COMFORT, PREMIUM

- High quality, low-e horizontal washing machine with 6 brushes

- Precise positioning table and lift-over unit for highest accuracy

- 12 foil rolls directly above the line

- Pre-laminator with convection, radiation and a combination of both

- Servo spindle press for highest precision, also with shapes

- Automatic recipe adjustment in the pre-laminator

What functions can be optionally added?

- 18 or 24 roll foil magazine

- Paternoster foil magazine for 6 additional rolls

- Automatic glass loading of the lamination line

- Eco-Heater for energy savings of up to 40%

- Connection to ERP software

- Pre-laminator design with double press

- Automated data transfer to higher-level planning systems

- Delivery of the climatic chamber

- Delivery of the autoclave

- Smart pressing technology

- Available in 3 variants: compact, comfort, premium

- Cost-effective, single-storey laminated glass line, low rooms or requirements where three, nine or twelve film magazines are sufficient

- Simple operation

- Intelligent and precise pressing technology

- Flexible production of special shapes and architectural glass

- Laminated glass line available in straight and U-shaped versions

- Processing of PVB and SGP

- Three, nine or twelve roll film magazines above the line (six rolls are standard)

- Paternoster film magazine for 6 additional rolls next to the line

- Eco-Heater for energy savings of up to 55

- Connection to ERP software

- Automatic glass loading of the Lami line

The Highlights

Up to 50 laminates per hour

Intelligent line design enables efficient production of standard formats even on large systems.

Low running costs

Only one operator in assembly with minimal energy consumption for air conditioning and thermal treatment in the pre-laminate.

Extremely simple operation thanks to a high level of automation

Automatic assembly and automatic recipe adjustment in the pre-laminate reduce the influence of the operator on the quality of the laminates.

- Systems & Lines

- Individual Machines

- Software