Individual Machines

Flat Glass Cutting

- LiSEC

- Individual Machines

- Flat Glass Cutting

- DSC-A

DSC-A

Automatic glass cutting machine for float glass - State of the art technology

The automatic glass cutting machine of the DSC-A series combines the latest drive technology with decades of LiSEC know-how in processing flat glass for every requirement. A completely newly developed structure of the table as well as a new cutting bridge and a new cutting head improve the stability and precision of the cutting process. A powerful low-e deletion system with grinding wheel in combination with a strong vacuum system for all common types of special coatings ensure a residue-free, fast and homogeneous low-e deletion result.

How is the DSC-A configured?

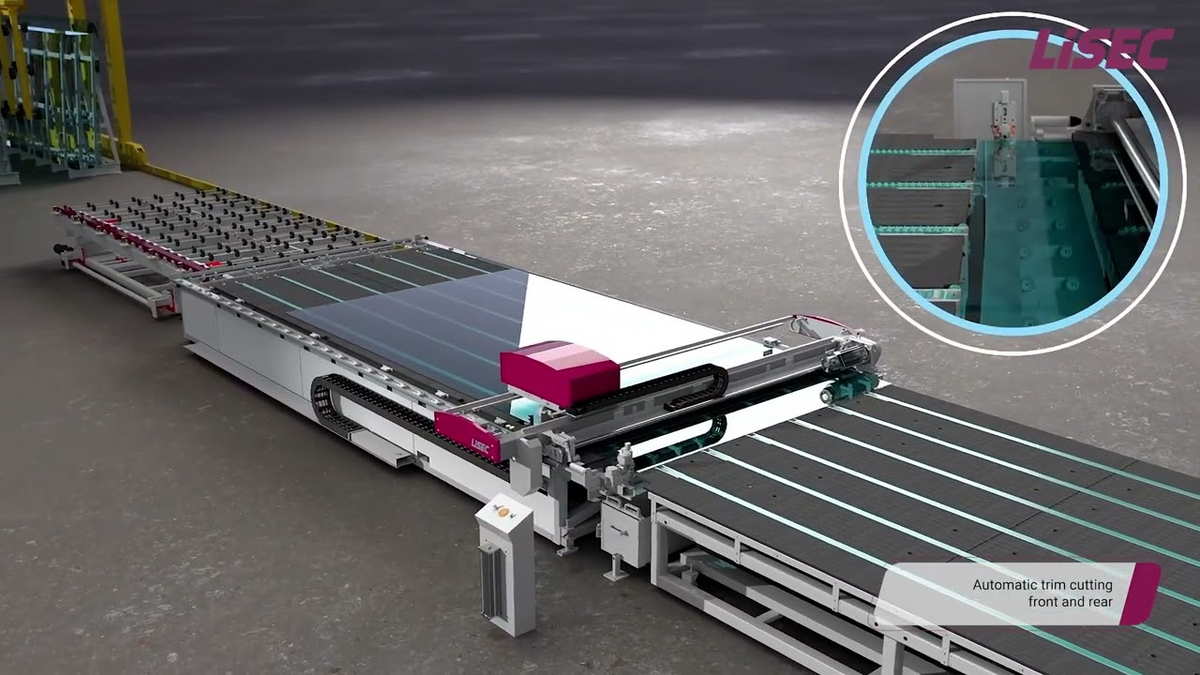

The DSC-A basic variant consists of a horizontal cutting table, equipped with conveyor belt, to combine this system with automatic feeding.

The DSC-A T-float glass cutting table has a tilt function as standard to facilitate manual loading and unloading of sheets of glass. The cutting table can be additionally equipped with conveyor belts and breaker bars.

Who is DSC-A suitable for?

The proportion of protective solar or thermal insulation coatings in insulating glass is increasing and the coating systems are becoming more and more complex, to facilitate a more energy-efficient design of the façades.

Thanks to the new LiSEC edge deletion technology, the DSC-A quickly and efficiently processes silver thermal protection (1-3-fold silver), as well as protective solar coatings and coating systems with a protective layer (TPF or Easypro). The proportion of complex coatings will further increase in the future and the DSC-A is prepared for these challenges due to the newly developed grinding head and bridge design.

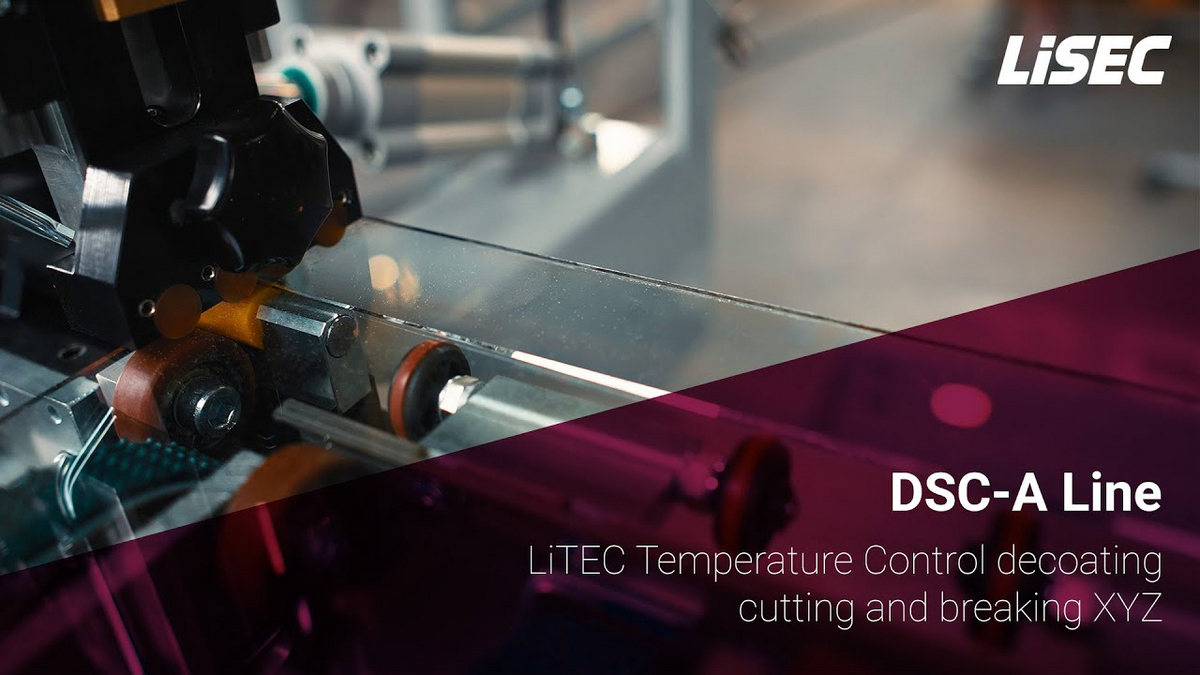

The glass-cutting table features LiSEC direct cutting technology and a gantry drive on the X-axis, thereby assuring precision of +/- 0.20 mm. Operation is even easier thanks to automatic cutting pressure control and the new grinding pressure control. Different grinding and cutting pressures are automatically set, depending on the coating and the glass thickness.

Cutting oil and cutting wheel monitors show the consumption and preventively indicate a change. Stock sheets of glass are sent in automatically on the conveyor belt and fully automated alignment is carried out by glass positioning aids.

- Precise glass cuts and high edge strength with LiSEC direct cutting technology

- Optionally up to 160 m/min low-e deletion speed with reinforced suction including HEPA filter unit

- 360° grinding in one cycle

- Automatic pressure control of grinding and cutting heads

- Display of cutting wheel consumption and critical cutting oil level

- Edge deletion on low-e glass lites sheets (Grinding wheel width of 20 mm to 26 mm)

- Fully automatic tool changer for cutting wheels

- Integrated fixture for cutting off remnant formats (RP-I)

- Multi-touch version of the control unit

- Tiltable design with breaker bars or belts (DSC-A-T)

The Highlights

Fast and high-quality cutting

The automatic electro-pneumatic control system enables constant cutting pressures in every situation, ensuring precision and the highest edge quality.

Perfect edge deletion

High speeds in combination with a newly developed grinding dust extraction system that can be adjusted to the glass surface ensure residue-free deletion of thermal insulation, sun protection and special coatings.

Fastest cycle time with cutting and grinding speeds of up to 160 m/min

Cutting and grinding speeds of up to 160 m/min are possible, thanks to LiSEC direct cutting technology and a fully revised grinding system with special grinding wheel

- Systems & Lines

- Individual Machines

- Software