Systems & Lines

Logistic systems

- LiSEC

- Systems & Lines

- Logistic systems

- IG-Sort Maxi

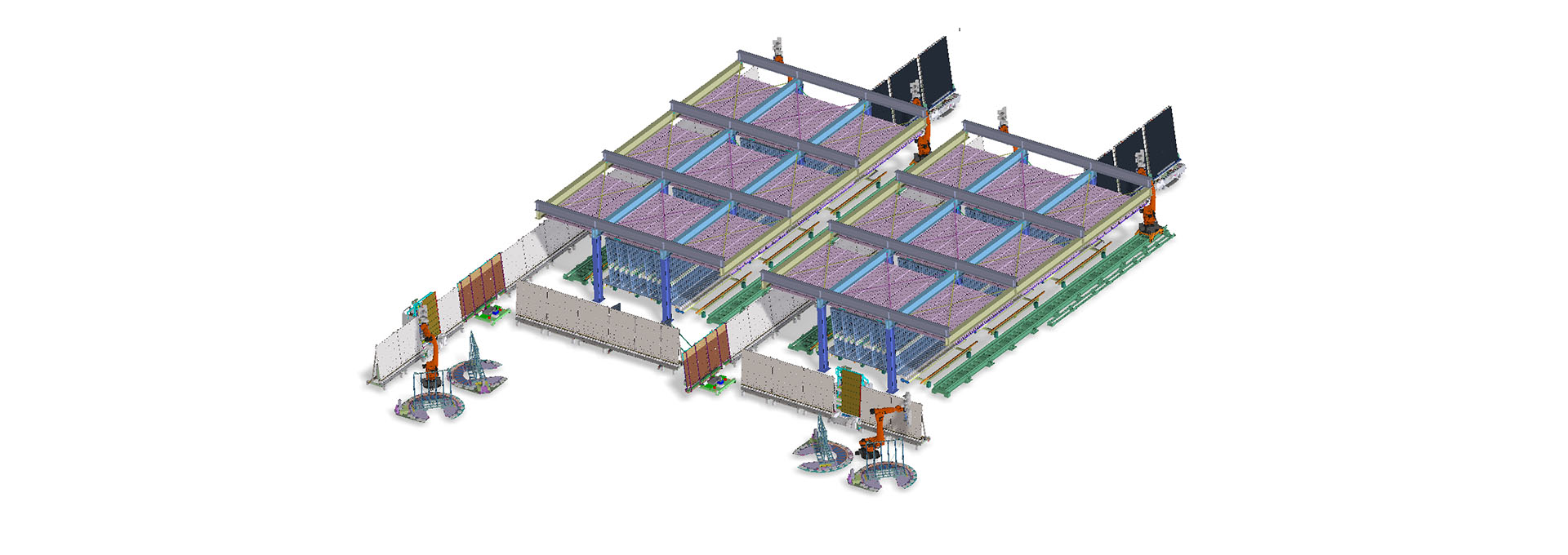

IG-Sort Maxi

Two insulating glass lines coupled for greater productivity

A frequent challenge in the dispatch process arises when shipping racks are assembled from two insulating glass lines. Lengthy search times, complex handling and the large amount of space required for the insulating glass quickly lead to a bottleneck in the process. The IG-Sort Maxi from LiSEC is the perfect solution here: the system ensures organised interim storage, rapid access to each individual insulating glass unit and efficient loading of the shipping racks – without time-consuming detours or manual searches.

What makes the IG-Sort Maxi unique?

This is an innovative production solution involving coupling two insulating glass lines. The result is a new type of production concept that dispenses with conventional production logic. The material flow is optimised and the carry-over of secondary sealing material is completely avoided. The system enables set-up time-optimised production with direct access to each individual unit – regardless of position. With a storage capacity of over 1,000 insulating glass units, high production flexibility is guaranteed and efficient throughput is a given.

What advantages does the system offer?

The IG-Sort Maxi automates handling at the end of the insulating glass line, enables the tempering, sorting and stacking of insulating glass units in the required sequence and improves productivity by decoupling customer-related batches.

- The system enables the automatic ejection of waste insulating glass units and autonomous handling of remakes.

- There is no subsequent completion of glass storage racks in the dispatch department, which leads to a reduction in the physical effort required of employees.

- Cycle time-neutral and automatic intermediate buffering of remakes downstream of the insulating glass line, so that only glass storage racks ready for dispatch leave the insulating glass line and no time is required for searching in the dispatch department

- Coupling of two insulating glass production lines

- Patented process for handling insulating glass

- Only racks ready for dispatch leave the insulating glass line

- No manual sorting of remakes in dispatch

- Unbeatable unit quality with thermoplastic spacers

The Highlights

Autonomous production

The insulating glass buffer realises fully automatic insulating glass production

Enhanced productivity

The decoupling of customer-related batches through set-up time-optimised batch sizes

Modular assembly

The composition of the heights, lengths and numbers of slots can be individually configured according to customer requirements.

High-end solution of a fully automatic buffer system for sealed units

The sorting system is fully automatic, which ensures the highest quality.

Cycle time gains

The insulating glass buffer ensures continuous output at the insulating glass production line.

- Systems & Lines

- Individual Machines

- Software