Individual Machines

Flexible Spacer Application

- LiSEC

- Individual Machines

- Flexible Spacer Application

- VSA-N

VSA-N

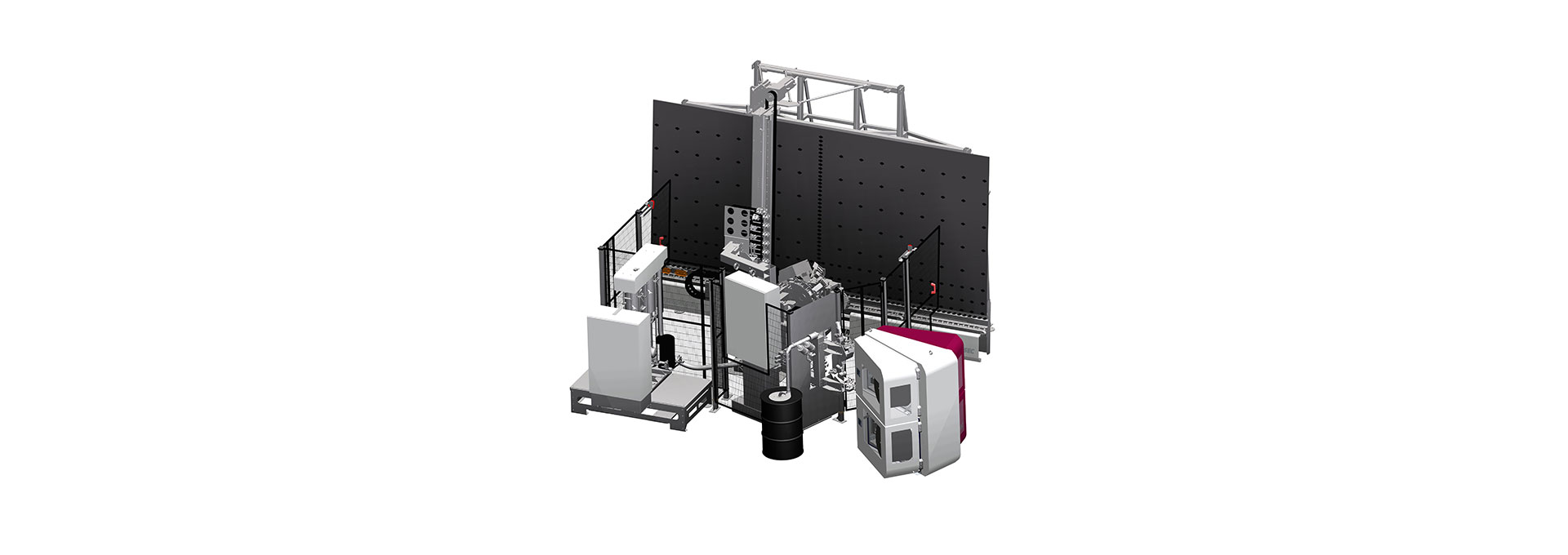

Fully automatic high-end system for applying flexible spacer belts to glass sheets

The VSA-N is a fully automatic system with a two-track application head for applying flexible spacer belts from rollers to glass sheets. The patented application enables highly precise and dimensionally stable positioning as well as for the frictionless and careful application of the spacer bar within unprecedented short cycle times.

How is the VSA-N configured?

The glass transport of the VSA-N consists of a transport wall with support rollers and divided drive zones. An additional directly attached additional suction beam guarantees precise glass transport. There is an application head on the vertical axis. This is supplied with material via a air-conditioned material box. There is a butylation system on the application head for double-sided butylation of the spacer.

How does the automatic processing of flexible spacers work?

The process begins with the positioning of the sheet by means of a sensor. The sheet is measured via a sensor in the in-feed section. As soon as the sheet is in position, the application procedure starts. The spacer is transported to the application head via an air-conditioned box. There, the protective film is suctioned in and the spacer butylated. The spacer is then pressed onto the sheet.

Who is the VSA-N suitable for?

Every insulating glass manufacturer can benefit from this system. From the small company that uses it to process all products, to the highly automated operation where one-off units are produced manually. The use of high-quality components keeps operating and maintenance costs to a minimum.

What advantages does the VSA-N offer?

The VSA-N is ideally suited for the production of double, triple and quadruple insulating glass units. Due to the design of a two-track application head, the cycle time is enormously reduced and production is uninterrupted. The working environment remains highly clean and tidy due to the automatic disposal of the punching waste. The angle-adjustable knife is only responsible for punching the corner pieces and is therefore permanently adjusted to the required height of the spacer material processed. This enables precise punching of the corner pieces, resulting in an exact formation of the corners.

- Application of a wide variety of flexible spacer types with widths from 8 - 20 mm

- Continuously circulating application with perfect angle structure

- Processing of spacer material with plastic foils

- More precise glass transport

- Stationary butylation for exact metering of butyl cord and processing of T-spacer material

- Angle-adjustable knife is fixed to the appropriate height of the processed spacer material

- Special sag control for exact metering of the butyl application: The beginning and end marks of the butyl cord are reduced to a minimum and cannot be identified on pressed and finished insulating glass units

- Clean working environment due to controlled disposal of all punching waste

The Highlights

Continuous all-around application with perfect corner shape

The free-cutting device clears the area of the corner, enabling an optimal corner finish.

Optimal storage of the spacers due to air-conditioned and humidity-controlled magazine.

The spacers are stored at optimum temperature in an air-conditioned magazine. This area is checked by means of a moisture sensor to ensure perfect processing of the spacer.

Small space requirement compared to conventional spacer systems

The space requirement is considerably reduced by this technology. The flexible spacers can be stored in a space-saving manner.

- Systems & Lines

- Individual Machines

- Software