Individual Machines

Robot Handling

- LiSEC

- Individual Machines

- Robot Handling

- PDL-A (A-rack)

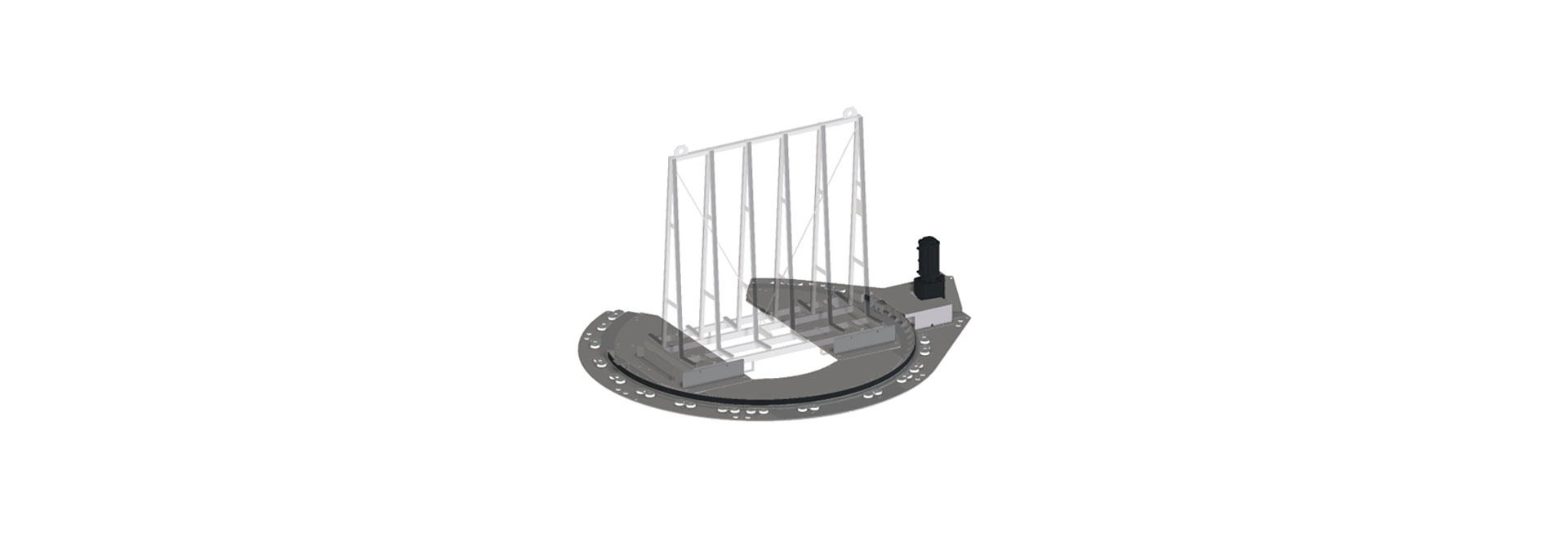

PDL-A (A-rack)

Rotating platform for glass transport racks for double-sided loading

The LiSEC PDL-A is an innovative rotating platform, specially developed for the rapid loading of glass transport racks on both sides. It enables uninterrupted removal of the racks using an industrial truck.

How is the PDL-A configured?

The rotating platform is designed for double-sided glass transport racks (A-rack, 180° rotatable). If available, existing glass transport racks can be used, provided they correspond to the dimensions. There is a recess in the sub-structure to allow various industrial trucks to drive underneath.

How does the LiSEC PDL-A work for loading glass transport racks?

The glass transport racks on the rotating platform are automatically loaded by a robot. The platform can be rotated through 180°. Placing or picking up a glass transport rack on the rotating platform can take place manually using a hand pallet truck, forklift or a similar industrial truck.

Who is the PDL-A rotating platform suitable for?

The rotating platform for double-sided glass transport racks is suitable for all companies looking for a solution for fast and uninterrupted loading and unloading of glass on glass transport racks.

What advantages does the system offer?

By using a LiSEC PDL-A, pre-filled glass transport racks for double-sided loading can be quickly removed without interruption. Optimised accessibility and a well conceived safety concept ensure a high degree of user-friendliness.

Technical Data

Technical Data

| PDL-A (A-rack) | Technical Data |

|---|---|

| Load per position of a glass transport rack for double-sided loading up to max.: | 3500 kg |

| Dimensions of glass transport rack (A-rack) max.: | 3200 x 1150 mm |

| Glass transport rack width min. (mm): | 1200 mm |

| Glass size min.: | 400 x 250 mm |

| Glass size max.: | 4000 x 3300 mm |

| Rotatable: | A-rack, 180° |

- Rapid loading

- Uninterruptible removal

- Optimum accessibility

- High degree if occupational safety

- Option of using existing glass transport racks

The Highlights

Uninterrupted rack changeover

Operation of the system is not interrupted by the removal of the filled glass transport racks. This ensures optimum utilisation of the system and enables the glass transport racks to be replaced quickly.

Use of existing glass transport racks

If glass transport racks are already available for loading on both sides, these can be used provided they satisfy the dimensions.

- Systems & Lines

- Individual Machines

- Software