Systems & Lines

Logistic systems

- LiSEC

- Systems & Lines

- Logistic systems

- Slot rack system with side loader removal

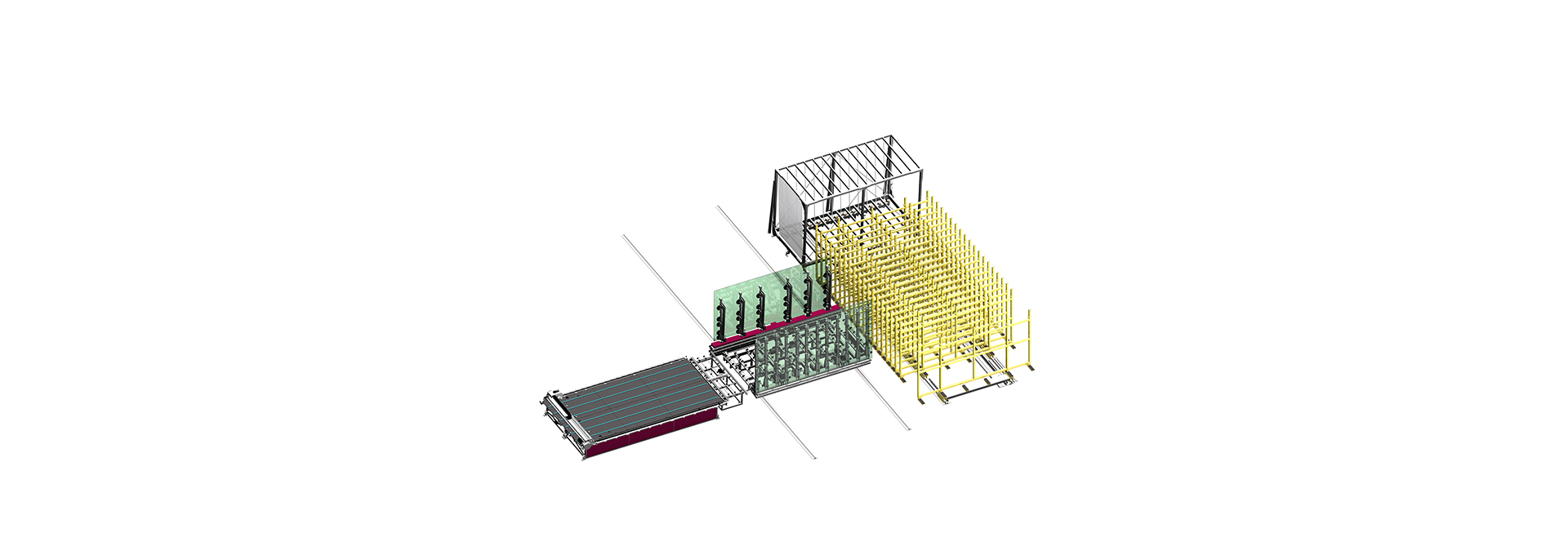

Slot rack system with side loader removal

Fully automatic, mobile glass loading station with linear cantilever

The SLR side loader is a system for removing large-format glass sheets from automatic mobile slot racks (LBR).

How is the SLR sideloader structured?

An SLR sideloader system is often combined with a mobile slot rack (LBR).

SLR sideloader

The sideloader is a removal station with a telescopic arm. This is a machine that can be moved on one or two sides and removes glass sheets from the slot rack fully automatically. The machine is installed on the floor, does not require a crane track and is easy to operate, resulting in straightforward maintenance.

LBR slot rack system

The LBR is an automatic slot rack for raw glass sheet formats. The stock storage system is characterised by a highly space-saving arrangement of L-shaped racks on heavy support rails. Up to 30% more storage space can be achieved with the same space requirements, when compared to a conventional store with storage racks. Furthermore, it is possible to increase the number of glass types in the slot rack system by up to 100%.

How does the SLR side loader system work?

The removal station automatically moves to the removal slot and brings the table board into a vertical position. At the same time, the slot rack of the selected glass type opens. As soon as the position is reached, the telescopic loading arm moves into the rack, with sensors determining the distance to the glass surface. The arm then navigates to the removal position, suctions the glass using vacuum suction cups, and separates it from the glass stack. The glass is transported to the handover station on the SLR while the table board tilts into a horizontal position. Outfeed of the raw glass sheet then takes place automatically into the downstream system.

Who is the SLR side loader suitable for?

The floor-mounted sideloader system is suitable for all operators who want to dispense with the crane girder normally used. The system can therefore be used in any type of hall. The slot rack is particularly suitable for a large number of glass types and limited available space.

- Space-saving due to extremely compact design

- For a large number of glass types

- Customisable for flexible production

- Variable expansion possible

- Systems & Lines

- Individual Machines

- Software