Individual Machines

Frame Processing

- LiSEC

- Individual Machines

- Frame Processing

- FSI-A

FSI-A

Station for positioning spacer frames and inspecting glass sheets

The FSI-A is a semi-automatic inspection and frame positioning station for rigid spacers used in insulating glass production. The station enables ergonomic glass inspection and manual cleaning thanks to an accessible rear compartment. The automatic height adjustment of the roller bars ensures gentle positioning of the glass panes. Safety features such as safety fingers when entering the rear compartment, as well as optional lighting and climbing aids, enhance ease of use. The FSI-A is available in various size combinations and can be flexibly adapted to customer requirements.

How is the FSI-A constructed?

The FSI-A is based on a stable steel construction consisting of horizontal and vertical torsion-resistant steel frames. The dark rear wall serves as a visual inspection surface and enables the detection of glass defects and contamination. The glass panes are transported via a roller conveyor with a split drive, so that up to two glass panes can be on the system at the same time.

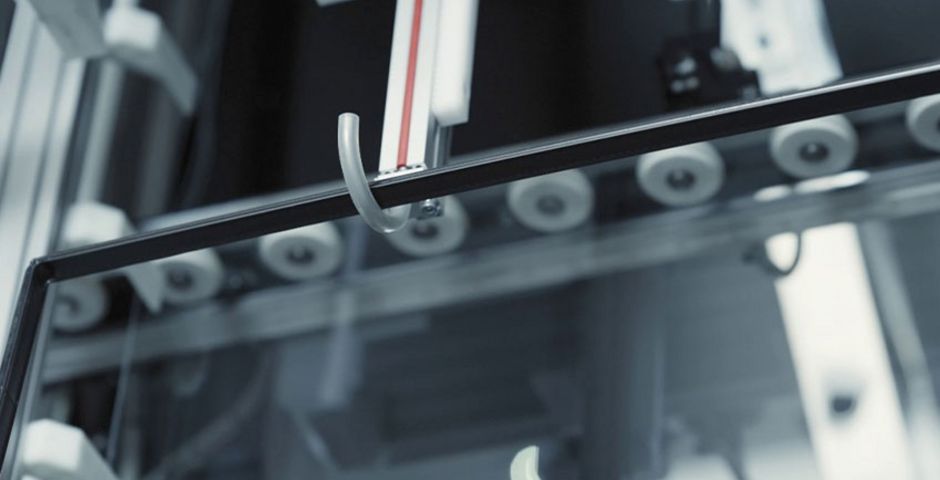

A horizontal roller bar is precisely positioned along the upper edge of the glass by means of a servo drive and several sensors. Lateral guidance is provided by vertical axes made of system profiles and roller guides.

How does the FSI-A work?

Before the glass pane is transported in, the horizontal roller bar automatically positions itself at the upper edge of the pane. Depending on the height, additional roller bars prevent sagging. The pane is pulled in via a roller transport with a split drive and positioned precisely with the aid of sensors.

The horizontal and vertical frame setting stops (attached on the outlet side) and frame insertion dimensions are then adjusted to enable precise placement of the spacer.

This is followed by inspection of the glass pane and cleaning if necessary. The spacer frame is then positioned manually on the pane. After confirmation of the inspection or frame setting process, the frame setting stops return to their home position and the pane is transported out.

Who is the FSI-A suitable for?

The FSI-A is the ideal solution for insulating glass manufacturers who set the highest quality standards and attach particular importance to manual control, thorough cleaning, and precise frame setting. It offers flexible adaptation to different glass sizes, enables ergonomic inspection and cleaning processes, and supports manual frame setting with maximum accuracy.

What are the advantages of the system?

The FSI-A offers numerous advantages, including a walk-in rear compartment with two different levels to allow flexible response to different glass sizes. The dimmable lighting on the roller beams makes inspection work much easier, as even the smallest defects and dirt can be quickly detected. The optimal design of the mechanics and stops ensures precise positioning of the spacer frame both horizontally and vertically. In particular, the automatic frame setting function at the top edge significantly simplifies the setting of large and long frames. In addition, various options for climbing aids at the front and rear allow the FSI-A to be perfectly adapted to the individual requirements of the customer.

Which functions are included as standard?

- The FSI-A is equipped as standard with an accessible rear compartment comprising two different working levels.

- The stops are integrated at the front:

- Vertically in the automatic version

- Horizontally in the automatic version

- The adjustment range of the frame stop is:

- Horizontally: 0–30 mm

- Vertically: 0–230 mm (maximum side step 200 mm)

- The standard glass support for the stops is designed for a glass thickness of 26 mm. In addition, automatic measurement of the frame width is already included as standard.

Which functions can be added as options?

- Dimmable lighting for the roller bars

- Dimmable lighting for the rear compartment

- Automatic frame setting at the top edge

- Frame positioning aid at the top edge via stop

- Climbing aid at the front

- Climbing aid in the rear area

- Processing of glass up to 60 mm thick

- Processing of 3 side steps (0–1000 mm)

- Processing of bottom edge steps up to 150 mm

- Support for special shapes A + B

- Optional version of the system without frame setting stops (inspection station)

- Perfect illumination of the glass pane

- Precise positioning of the frame setting stops

- Optimal accessibility of all areas

- Guidance of the glass pane via automatically aligned horizontal beams, reducing contact points with the pane and creating more space for inspection and cleaning

The Highlights

Automatic frame positioning at the top edge

The device is mounted directly on the axes of the roller beams and enables large frames to be positioned automatically at the top edge. In combination with the climbing aid at the front, frames can be inserted manually in any configuration – regardless of size and format. The horizontal stop at the top edge then takes over the complete positioning and fixing of the frame. This interaction ensures precise, repeatable attachment, reduces manual effort to a minimum, and ensures reliable integration into the production process.

Climbing aid in the rear of the system

The climbing aid integrated in the rear area makes it much easier to inspect and clean large panes. Even areas that are difficult to access can be reached easily and comfortably. The ladder can be positioned flexibly and aligned according to the location of the contamination or the area to be inspected. After use, it can be adjusted so that it is outside the movement range and does not interfere. This system enables safe handling, reduces downtime, and improves ergonomics during maintenance and cleaning work.

Automatic detection of spacer width

Thanks to a compact mechanism integrated directly into the lower horizontal stop, the frame width is determined immediately at the system without any additional loss of cycle time. The exact width measurement provides essential process information for the safe further processing of the insulating glass element—especially during the subsequent pressing process. This solution increases process reliability, reduces sources of error, and ensures precise adaptation to different frame sizes.

- Systems & Lines

- Individual Machines

- Software