Individual Machines

Edge Processing

- LiSEC

- Individual Machines

- Edge Processing

- KSD-A

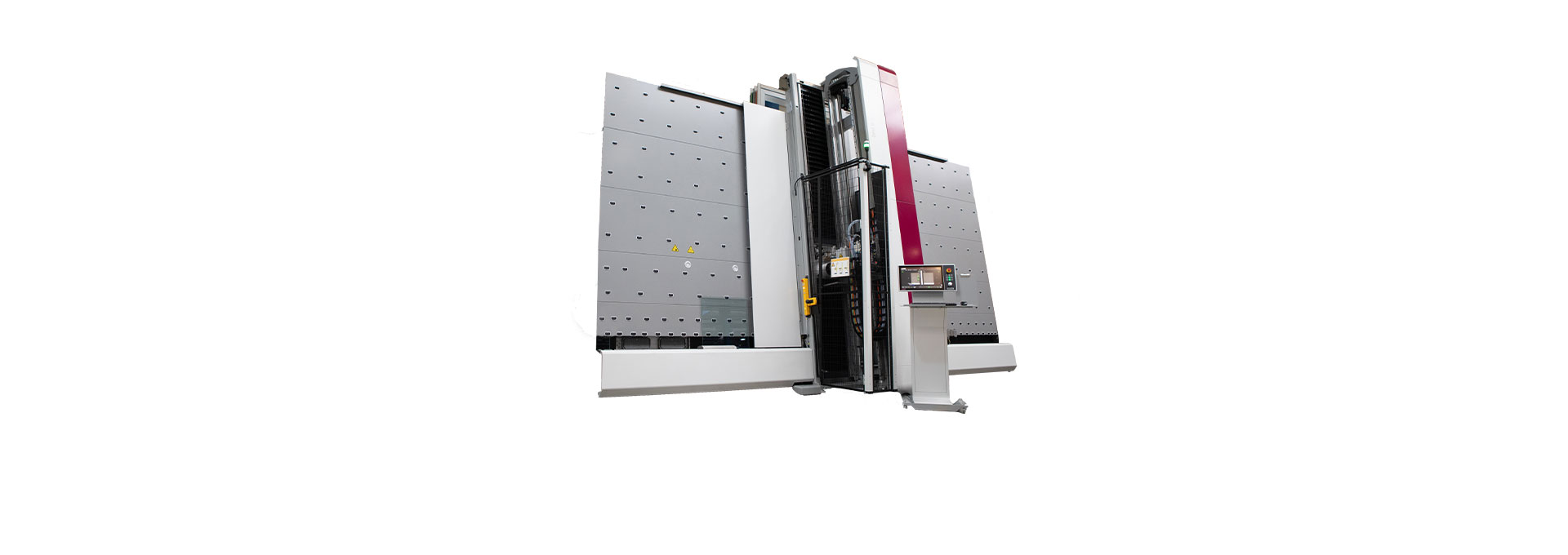

KSD-A

Rapid vertical edge seaming and grinding machine for glass with LiTEC slider technology

The KSD-A from LiSEC is currently the fastest vertical seaming and grinding machine with peripheral wheels for the processing of glass edges, e.g. the seaming and grinding of glass edges. This machine combines massive processing flexibility with stable and reliably high quality. With decades of experience in glass edge and the courage to break new ground, the KSD-A is also a defining technological landmark for the future of glass edge processing.

KSD-A machine – perfect seaming quality, every time

The seaming machine delivers perfect quality, even on glass with breakage quality. Its innovative LiTEC slider technology ensures that the tool is 100% self-regulating, allowing for flawless results on glass sheets. This capability guarantees perfect seaming quality despite geometric inaccuracies, as the tool can automatically adjust to accommodate these variations. In addition, the seaming machine excels at handling glass sheets, thanks to its self-positioning grinding tool that seamlessly adapts to any situation.

How is the KSD-A configured?

Depending on the machine length, the LiSEC KSD-A consists of several elements in a modular construction. At the heart of the system is the processing tower with a high-speed X-axis for glass transport and optionally one or two processing heads mounted on separate vertical axes. The perfect waterproofing of the axes against humidity ensures long-term stability and easy accessibility.

How does the KSD-A work?

The KSD-A was developed for particularly fast cycle times and a very high level of flexibility. The glass sheets being processed are received by a high-speed axis with suction cups, which measures the position of the sheet at all times. After automatic measurement of the height of the glass sheet “on the fly”, the edge can be seamed or ground in any desired number of cycles. The flexible tool configuration allows processing of different glass thicknesses without changing tools.

How does the new LiTEC slider tool work?

The tool and the technologies employed play a key role in the detection of defects. Especially when seaming glass edges, due account needs to be taken of faults in the glass such as break quality, flatness, geometric irregularities etc. With the new LiTEC slider tool, all of that becomes past history. This new technology now also transmits this outstanding grinding belt flexibility to diamond grinding belts.

Who is the KSD-A suitable for?

The KSD-A is a universal seaming and grinding machine for all glass processors who need stable and high-quality edge processing without operator intervention. With its many configuration options, the system is ideally suited for the flexible processing of individual sheets and for the fast processing of insulating glass on the production line. Above all, the KSD-A is suited to glass processors who wish to produce ground as well as seamed edges, or who process special shapes.

What are the advantages of the machine?

The greatest advantages of the system are its perfect seaming quality - independent of the quality of the cut glass and its edge quality - and its outstanding processing flexibility. In contrast to conventional machines, the KSD-A is capable of seaming poorly cut glass. This capability remains consistent, even when breaks above and below the glass edge are severe. It can also handle glass cutting tolerances in both the sheet and geometry. Additionally, the KSD-A can consider any sheet offset, particularly in the case of cut laminated safety glass (LSG) sheets.

The tools allow flexible operation with different glass qualities and thicknesses without requiring tool changes. Any necessary tool change can be easily performed from the front in just a few seconds. This, combined with the fact that the system is designed for batch size 1, allows for maximum flexibility in production. Additionally, the KSD-A offers the option of grinding sheets with glass removal.

Which functions are included as standard?

- Automatic infeed and outfeed of the glass sheets

- Processing of float glass and laminated glass sheets with a glass thickness of 3-19 mm

- Automatic measurement of rectangles

- Seaming and grinding without glass removal

- Two sets of tools based on LiTEC slider technology

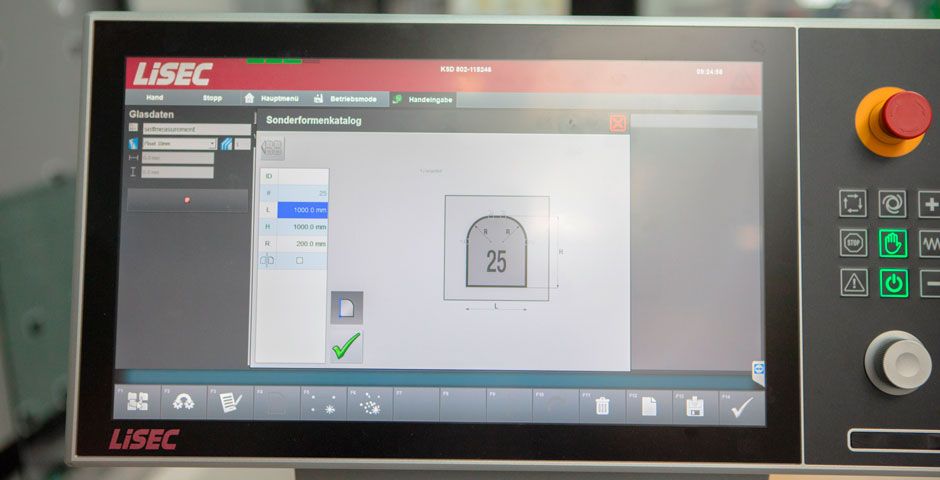

- Simple operating program with graphical interface

Which functions can be added optionally?

- Processing of special shapes including CAD/CAM drawing program.

- Grinding with glass removal

- Second processing head for even faster cycle times.

Do you want to know more about the product?

Click here: https://hub.lisec.com/litec-duo-order-sample

Technical Data

| KSD-A20 | KSD-A25 | KSD-A30 | KSD-A33 | |

|---|---|---|---|---|

| Maximum glass height (mm) | 2,000 | 2,500 | 3,000 | 3,300 |

| Maximum glass length | Modular | Modular | Modular | Modular |

| Minimum glass dimension | Seaming 350x 180 mm / grinding with material removal 700 x 180 mm | Seaming 350x 180 mm / grinding with material removal 700 x 180 mm | Seaming 350x 180 mm / grinding with material removal 700 x 180 mm | Seaming 350x 180 mm / grinding with material removal 700 x 180 mm |

| Glass thickness | 2.3-21 mm (seaming from 4 mm glass thickness) | 2.3-21 mm (seaming from 4 mm glass thickness) | 2.3-21 mm (seaming from 4 mm glass thickness) | 2.3-21 mm (seaming from 4 mm glass thickness) |

| Number of processing heads | 1 processing head standard, option of 2 heads | 1 processing head standard, option of 2 heads | 1 processing head standard, option of 2 heads | 1 processing head standard, option of 2 heads |

| Transport height | 520 mm / other transport heights on request | 520 mm / other transport heights on request | 520 mm / other transport heights on request | 520 mm / other transport heights on request |

| Tilt angle for glass transport | 6° | 6° | 6° | 6° |

| Tools | LiTEC slider - diameter: 150 mm / holder: HSK-50 | LiTEC slider - diameter: 150 mm / holder: HSK-50 | LiTEC slider - diameter: 150 mm / holder: HSK-50 | LiTEC slider - diameter: 150 mm / holder: HSK-50 |

- Perfect seaming quality every time, thanks to the use of LiTEC slider technology.

- Rapid seaming and grinding of a wide variety of glass sheets in one machine.

- Maximum dynamics and speeds of all axes.

- Optimised for use in insulating glass lines and after glass cutting.

- Automatic measurement of rectangles possible as standard.

- Flexible tool configuration for processing without tool change.

- Tool holder change directly from the front side of the machine. Tool set-up on the holder is possible during processing.

- Optional second processing head for even faster cycle times.

- Modular extension of the glass length possible with additional transport sections.

- Perfect waterproofing of all axes.

- Easy access to all components for service and maintenance work.

The Highlights

perfect seaming quality in every situation

By using LiTEC slider technology, the seam quality is no longer dependent on the quality of glass cutting. Even glass sheets with poorly cut or broken edges are processed reliably on the KSD-A.

fast and reliable

The machine was developed for use in highly automated lines, based on decades of experience in the processing of glass sheets. The KSD-A is a universal glass processing tool, combining the fastest possible cycle times with the utmost in reliability and flexibility.

diverse connection options

The machine's control options are as diverse as the customers' requirements. From the manual input and the automatic measurement of rectangles, to direct connection to the production control system, the KSD-A enables every form of integration in the production line.

- Systems & Lines

- Individual Machines

- Software