Individual Machines

Laser Processing

- LiSEC

- Individual Machines

- Laser Processing

- LDP-A – Laser Drilling Processing

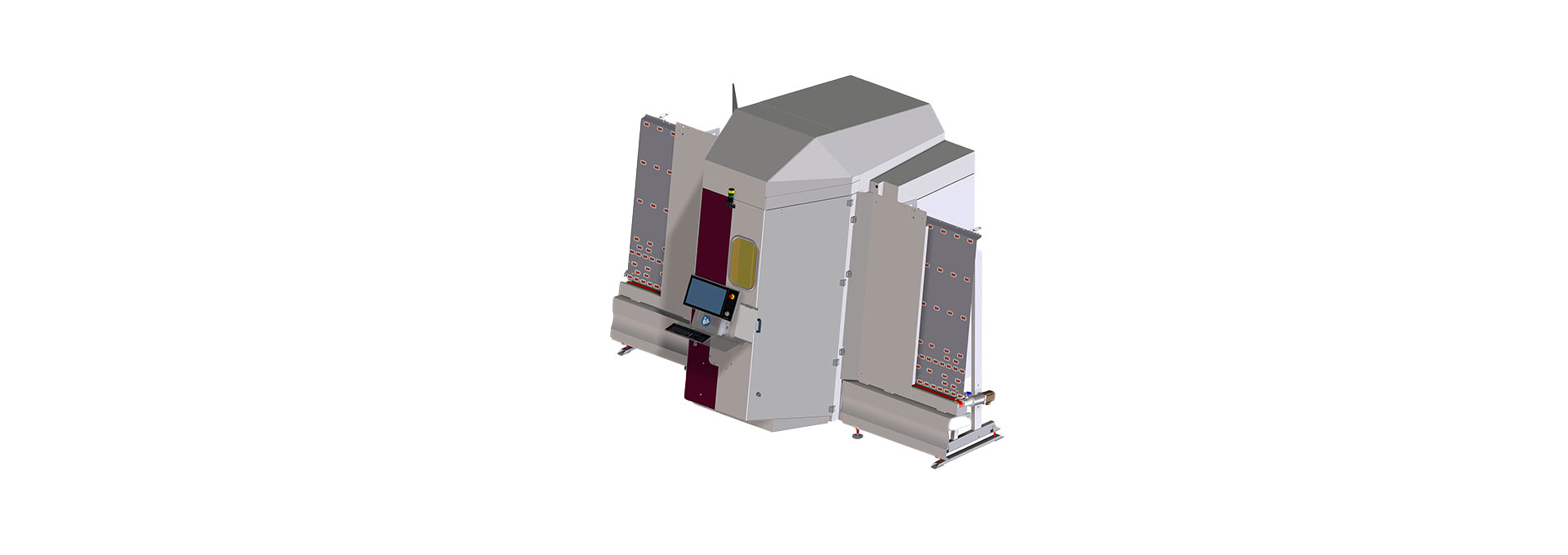

LDP-A – Laser Drilling Processing

Laser drilling for flat glass

The LiSEC LDP-A offers an innovative solution for drilling glass with unbeatable precision and efficiency. Thanks to the patented laser technology, a wide variety of shapes and sizes can be drilled without mechanical stress or ancillaries. Ideal for customised glass designs and industrial applications.

How is the LDP-A configured?

The LDP-A consists of a compact system with a vertical laser head. It can be operated as a stand-alone machine or fully integrated into a production line. The system enables glass to be drilled in a working area of 100 x 100 mm² and supports both round and free shapes.

How does the LDP-A work?

This system uses a laser that processes the glass without any contact or mechanical stress. The laser beam penetrates the glass and produces precise drilled holes with minimal thermal stress. The system requires no ink, granulate or chemicals and enables clean and efficient processing.

Who is the LDP-A suitable for?

The LDP-A is ideal for companies that require precise and efficient solutions for drilling glass. It is suitable for the manufacture of standardised and reproducible as well as decorative glass products, for the implementation of unique functional applications and for delivering on special industrial requirements.

- A high degree of precision and quality

- Flexibility in the processing different glass shapes and sizes

- Contactless and mechanically stress-free processing

- No ancillaries required

- Low operating costs and high efficiency

- Easy integration into existing production lines

The Highlights

Compact, vertical laser head for precise drilled holes

The compact, vertical laser head enables precise glass drilling with minimum space requirements. This design facilitates integration into existing production lines and ensures a high degree of flexibility during processing.

A high degree of precision and quality in glass processing

The LDP-A offers high precision and quality when processing glass, resulting in clean and exact drilled holes. This accuracy is particularly important for applications that require a high level of detail and repeatability.

Contactless and mechanically stress-free processing

The contactless and mechanically stress-free processing reduces the risk of microscopic cracks and other damage to the glass. This ensures a longer service life for the processed products and minimises waste.

Sustainability & longevity

Contactless machining without tools and additional material minimises the use of energy and foreign materials (especially drilling tools, water and sand) in production. This significantly reduces machine wear, extends maintenance intervals and thereby ensures a longer service life for the machine. At the same time, a complex water cycle becomes superfluous and energy consumption is drastically reduced.

- Systems & Lines

- Individual Machines

- Software