Individual Machines

Sealing

- LiSEC

- Individual Machines

- Sealing

- VL-1N

VL-1N

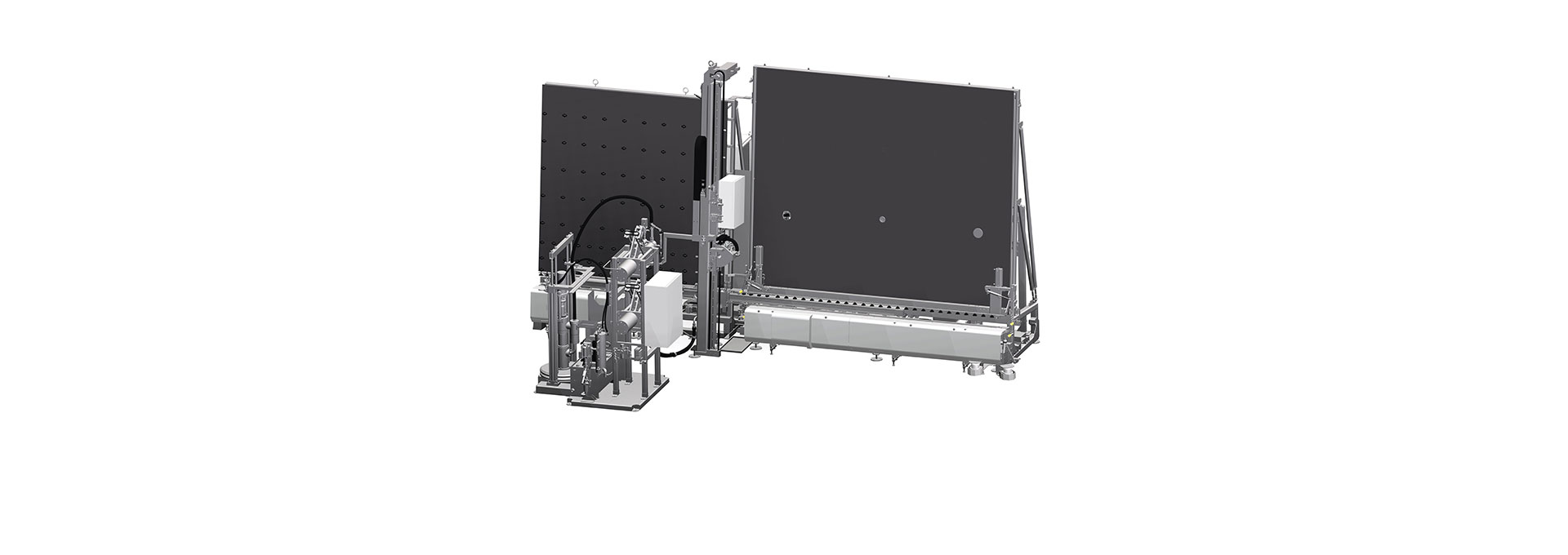

Fully automatic system for sealing insulating glass units

The VL-1N is a system for sealing insulating glass units with two-component sealants. The perfected build-up guarantees a high degree of process reliability and offers outstanding operator and service friendliness.

How is the VL-1N configured?

The VL-1N consists of an infeed section, a vertical sealing bar and an outlet section. The patented, wear-resistant transport chain supports the lower unit edge only slightly; the sealing cavity is kept free. From the run-out section onwards, a horizontal roller beam additionally guides the unit at the upper edge with a defined distance to the back wall.

How does the automatic sealing of insulating glass units work?

Unit thickness and build-up are measured in the separate upstream measuring section or via an ERP system and are known at the in-feed into the sealing machine. The unit length measurement takes place during in-feed transport. The frame inset is measured during the sealing process. Start of material application, carried out by a rotating application head on a vertical guide carriage in front of the station. Corner correction is subsequently carried out.

Who is VL-1N suitable for?

The VL-1N is an asset for every insulating glass manufacturer. From the small company that uses it to process every product and manually produces one-off units, to highly automated operations. The use of high-quality components keeps operating and maintenance costs to a minimum.

What advantages does the VL-1N offer?

The VL-1N is ideally suited for the production of double and triple units. The depth scanner on the applicator head delivers an exact material quantity calculation. An integrated automatic cleaning, spray and lubrication system ensures operation of the transport chain with no maintenance required. The integrated pneumatic coupling device, which acts as an interface between the machine and the material unit, ensures convenience when changing material. A higher cycle frequency is achieved by adding a LiSEC VLA.

- Corner correction: Corner rolling system for completion of glass units

- Continuously circulating application with perfect angle structure

- Wooden back wall with integrated, height-adjustable, horizontal roller beam that guides the upper edge of the insulating glass unit into the sealing sections

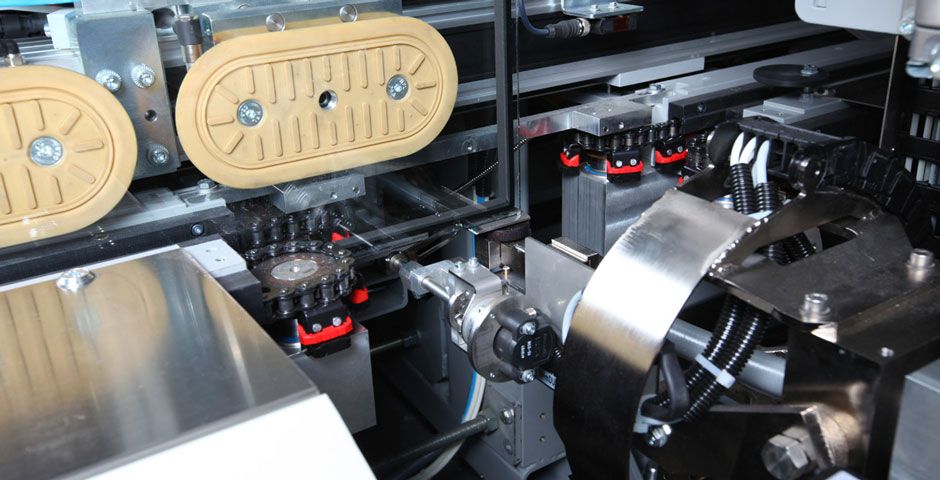

- Glass transport: patented, wear-resistant transport chain = precise glass transport

- Possibility of increasing the cycle frequency by adding a VLA

The Highlights

Uncomplicated mechanical build-up, which results in very high process reliability.

The straightforward and improved build-up delivers greater process reliability.

Homogeneous corner compaction through spatula division or roller system

The VL-1N impresses with its spatula division or roller system with homogeneous operation and with the unit corners.

Precision dosing system with quantity and speed control

The quantity and speed are controlled fully automatically by an innovative precision dosing system. This facilitates high-quality sealing of the insulating glass units.

- Systems & Lines

- Individual Machines

- Software