Individual Machines

Frame Processing

- LiSEC

- Individual Machines

- Frame Processing

- RHF-A25/25

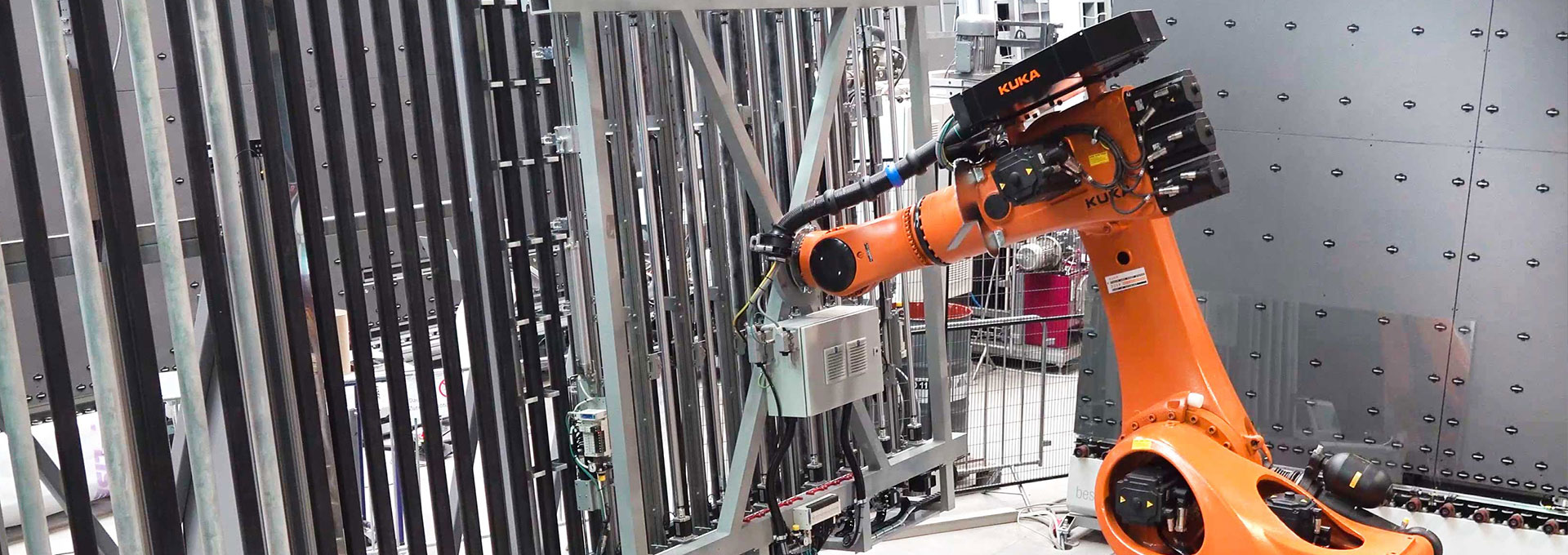

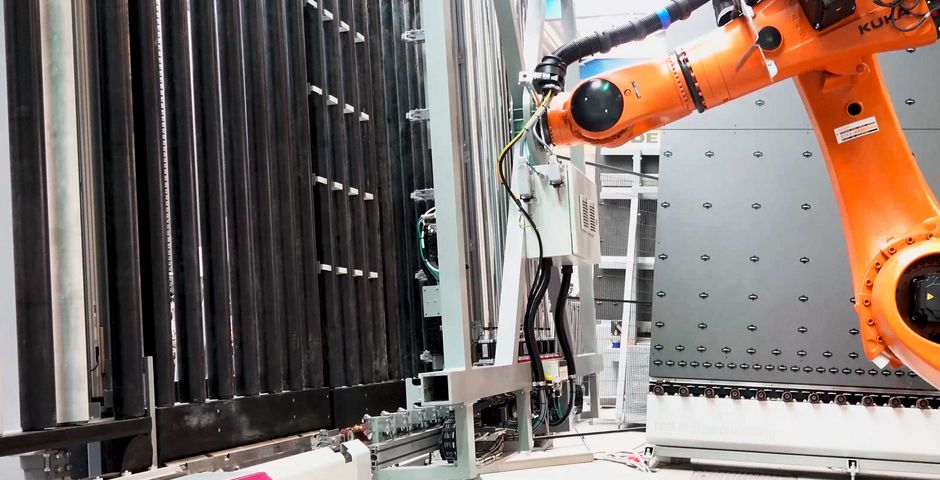

RHF-A25/25

Robot system for automatic frame mounting

A system of fixed and dynamically moving clamps ensures optimum alignment and the safe transport of frames with butyl applied to both sides. The robot arm mounts the stably clamped frame precisely on the glass with high positioning accuracy.

How is the RHF-A25/25 configured?

The RHF-A25/25 essentially consists of a six-axis articulated-arm robot and the frame clamping system mounted on it. The frames are ideally picked up by an automatic butyl extruder and placed against the glass, which is aligned at the required location on the insulating glass line.

How does the robot system for automatic frame mounting work?

The robot moves a stable clamp framework that grips the frame firmly on all sides and realises top quality mounting.

Who is the RHF-A25/25 suitable for?

The system is suitable for all common rigid spacer types, and it is even possible to process Georgian bars. The RHF-A25/25 is perfect for customers who are looking for a fully automatic, reliable frame mounting system. The continuous working process can significantly increase production output.

What advantages does this robot system offer?

Because the frame is always clamped on all sides, from the moment it is lifted off after butylation until it is mounted on the glass, this results in a reliable production sequence for all frame sizes. Additional advantages are the extended spatial possibilities that result from the robot's large range of motion. This means that frame production can be positioned at virtually any angle to the IG line.

- Rapid and reliable frame mounting

- Uniform frame insets on all sides

- Processing of a wide range of frame sizes

The Highlights

Rapid and reliable frame mounting

The sophisticated clamping system in combination with the precise robot delivers a fast and reliable frame mounting system with maximum accuracy.

Uniform frame insets on all sides

Thanks to the dynamically moving clamps, even deformed frames or frames sagging due to their own weight are always brought into optimum shape and aligned.

Processing of a wide range of frame sizes

The flexible clamp framework adapts to a wide range of frame formats within a very short time. The variable positioning of the dynamic clamps allows them to be optimally distributed along the respective length to ensure a secure hold.

- Systems & Lines

- Individual Machines

- Software