Individual Machines

Decoating

- LiSEC

- Individual Machines

- Decoating

- AKL-A

AKL-A

EDGE DELETION PLANT FOR SURFACE-COATED GLASS SHEETS

The vertical edge deletion plant, AKL-A, is equipped to work on all conventional surface-coated glass sheets. The LiSEC AKL-A grindes the edge of rectangles and other shapes. This development sets a high standard with regard to processing options. Removing the metal coatings from the edge areas of surface-coated glass sheets ensures that the butyl adheres properly.

How is the AKL-A configured?

The AKL-A is divided into 3 sections. These are the inlet section, the grinding section and the outlet section.

How does flat glass stripping work?

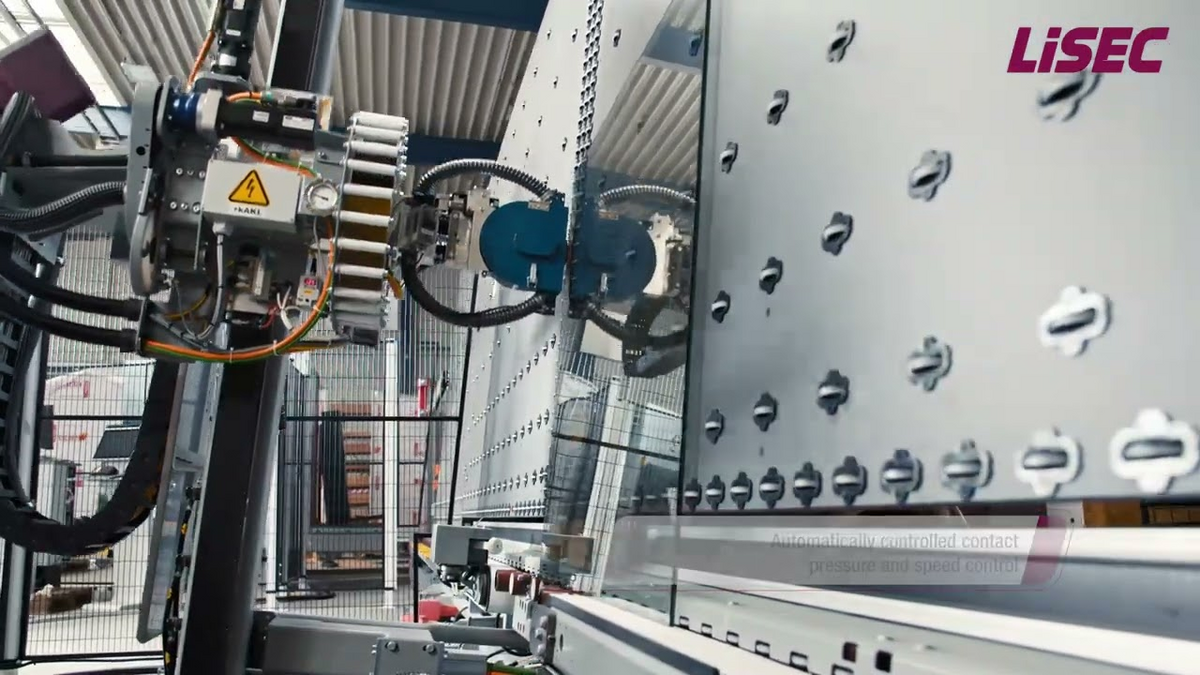

The machining process begins at the inlet section, where the glass sheet is transported towards the grinding section by means of a belt drive. In the grinding section, the glass sheet is then stripped by means of a grinding wheel. The grinding unit has a speed control function that adjusts itself according to the current wheel diameter. Coating residue and dust are removed using an automatic suction device. The sheet is then conveyed onwards to the outlet section.

For whom is AKL-A suitable?

Both small and large companies in the field of glass processing can benefit from the AKL-A, because optimum glass sheet deletion is the cornerstone of every good piece of insulating glass.

What advantages does the AKL-A offer?

The AKL-A works in a highly clean and precise manner due to its automatic extraction system and automatic speed control. In addition, the automatic coating detection function detects if a coating is present and also what side the coating is on.

- Edge stripping of rectangles and shapes in a single cycle

- Available as a stand-alone machine or with the option of integration into an insulating glass line

- Automatic extractor and measurement of the grinding wheel

- Constant grinding speed due to automatic speed correction

- In the case of rectangles, there is no overlapping of corner cuts

- Optimum program flow for a quick processing cycle

- Automatically adjustable suction device for grinding dust

- The grinding wheel width ranges from 10 to 26 mm

The Highlights

Improved grinding process

Due to the optimised grinding process, we are able to achieve a high processing quality in no time at all. Thanks to the improved process, overlapping corner cuts are a thing of the past. The grinding head, which can be continuously swivelled through 470°, means that even special shapes can be ground automatically.

Automatic deletion device and measurement of the grinding wheel

The automatic grinding wheel measurement function adjusts the speed to the respective grinding wheel diameter. Thus, an optimal grinding result can be achieved. The grinding wheel is kept in optimum condition at all times by the deletion device.

Machining of shapes and step grinding

Thanks to the innovative control system of the AKL-A, shapes such as triangles and curves pose no issues. Using a predefined shape, it is possible for the machine to generate a CNC code and use it for machining. With the IG Line Management software, LiSEC is able to offer a solution for managing shape data throughout the machining period of insulating glass production.

- Systems & Lines

- Individual Machines

- Software