Individual Machines

Sealing

- LiSEC

- Individual Machines

- Sealing

- APKV-A

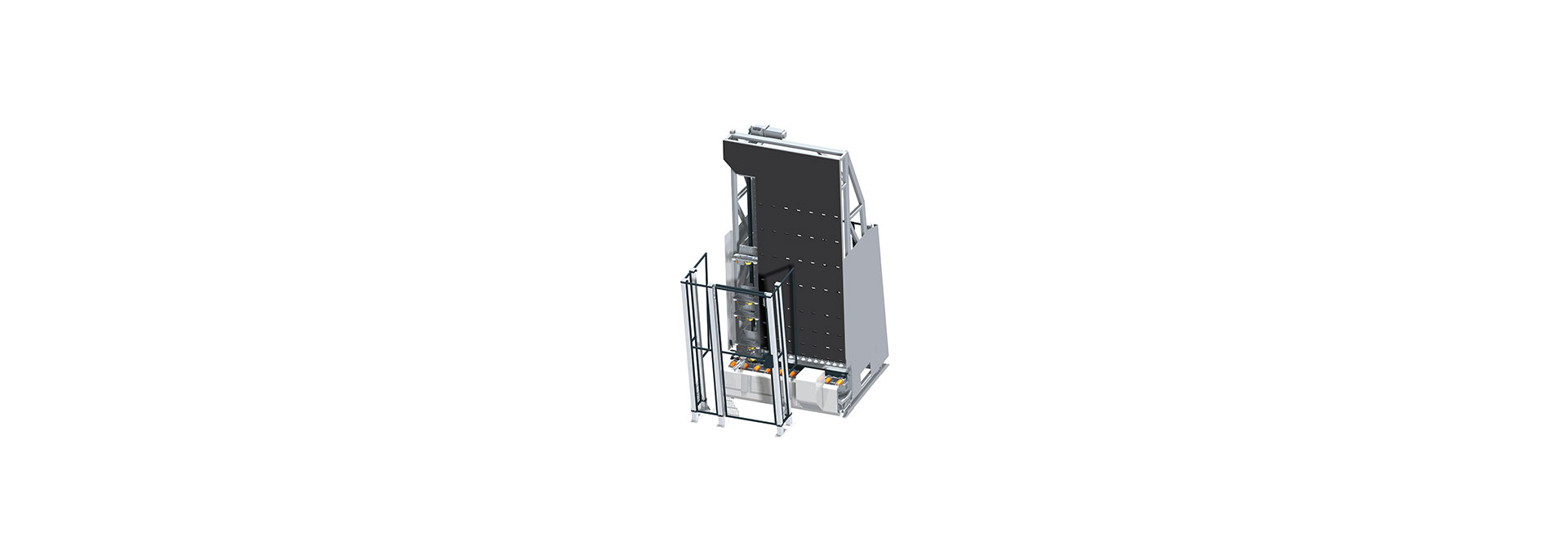

APKV-A

Fully automatic application device designed for the application of distancing cork pads

The fully automatic application device was developed to apply distancing cork pads to insulating glass units. It has a height measuring device and a movable applicator unit. There is a flexible choice between two and five application heads to meet individual requirements.

How is the LiSEC APKV-A configured?

The transport station of the APKV-A is equipped with an applicator unit and is usually positioned in front of an automatic sealing machine. The back wall of the system is fitted with recessed, easily replaceable special castors that allow the glass sheets to be transported safely and effortlessly. Glass transport takes place on belts that are equipped with a particularly resistant coating.

The program and electrical control system for the APKV-A is connected to the downstream main machine – an automatic sealing machine. The applicator heads are installed behind the glass transport track in the back wall of the system. If required, the LiSEC machine type APKVF-A can also be used for application from the front side.

Between two and five cork applicator heads can be selected, depending on the height of the glass sheets (see options). The adhesion points are determined by a control system that arranges them one above the other and one behind the other according to the respective glass size. The applicator unit for the first or bottom row is stationary, while the applicator units for the second to fifth levels are brought into the required position via separately assigned guide rails and an electronically controlled drive unit.

The uncoiling reels are positioned together with the applicator device on the rear side of the machine.

How does the APKV-A work?

The cork band moves through the measuring zone in the applicator device and is trimmed to the required length by a cutting device. The cork is then stamped directly onto the passing glass sheet using the cutting tool. The number of application points in the vertical arrangement is specified according to the glass sheet height in the process control program. The glass length and height are defined by an integrated measurement device or may be accepted via data records from a superior production control software system.

Who is the APKV-A suitable for?

The LiSEC APKV-A is the ideal solution for glass processors of all sizes, enabling them to automatically apply cork pads to insulating glass units or individual glass lites sheets. These pads ensure that the glass units remain separated during storage. Thanks to its maintenance-friendly design and robust construction, the APKV-A is a user-friendly and low-maintenance system.

What advantages does the system offer?

The system offers numerous advantages that guarantee optimum results for the customer:

- Flexibility: The number of application heads is optional and can vary between two and five.

- Integrated height measuring device: The system is equipped with a height measuring device and a mobile applicator unit.

- Efficiency: Speedy separation of cork pads takes place automatically, without manual intervention.

- Precision: The cork pads are precisely and automatically pressed onto the glass sheet.

- Precise and automatic pressing onto the glass sheet

- Application of the distancing cork pads from the rear side

- Pad positioning by means of an automatic program

- Up to five rows of pads

- Optional application of shapes according to the LiSEC shape catalogue

The Highlights

Variable number of application heads

The number of application heads can be adjusted depending on the size of the glass sheet, in order to reliably apply the optimum number of pads for the respective sheet.

Processing of different cork bands

The APKV-A can process different cork bands. Bands that have been tested and approved by LiSEC are stored in the approval list.

Application position via automatic program

The optimum position of the pads is automatically determined and applied by the program. Calculation of the positions can be adapted to individual requirements by means of adjustable parameters.

- Systems & Lines

- Individual Machines

- Software