Systems & Lines

Logistic systems

- LiSEC

- Systems & Lines

- Logistic systems

- IG-Sort Mini

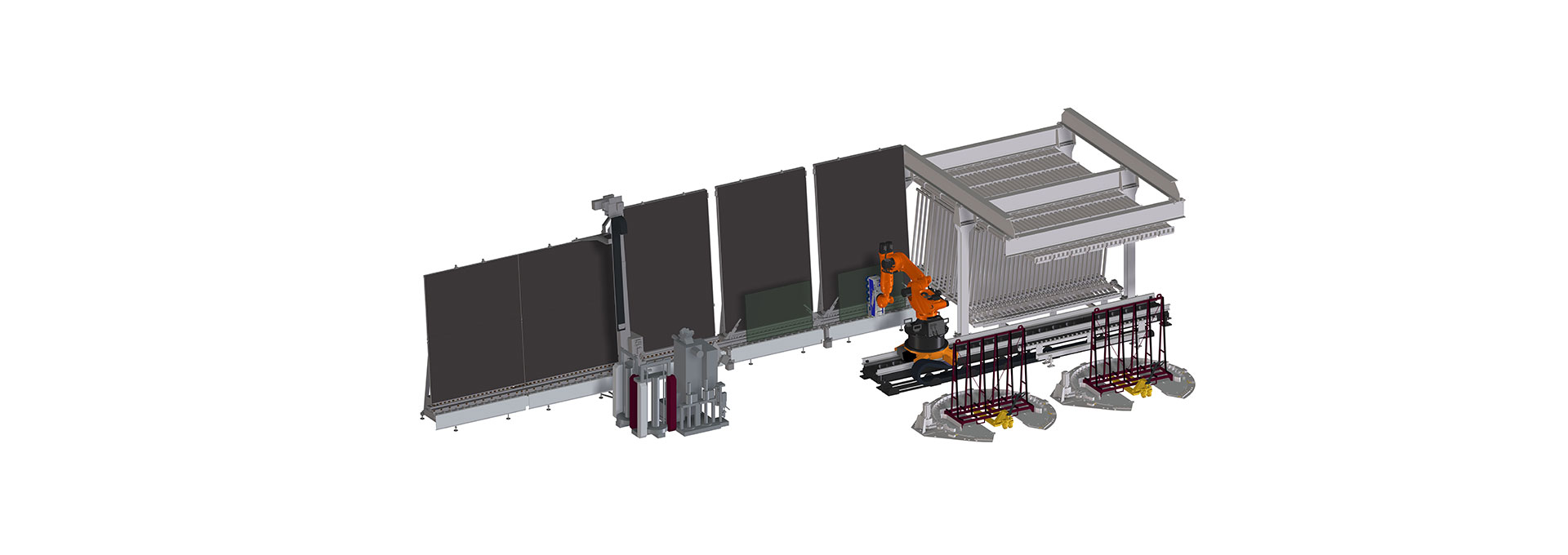

IG-Sort Mini

When the dispatch sequence of insulating glass units is of the utmost priority

A robot places insulating glass units on transport racks that are located on a rotating station and can be loaded on both sides. Once fully loaded, the racks are transported to the dispatch hall. Production errors or missing sheets can disrupt the sequence, resulting in the need for a remake. Manual intervention brings with it a risk of mistakes. The IG-Sort Mini from LiSEC offers the solution.

What makes the insulating glass buffer unique:

The damaged insulating glass unit and all subsequent units that complete the transport rack are placed in a buffer. The incomplete rack is removed from the rotating station and awaits completion. The rack is only completed once the remake has been produced and placed in the stock. The LiSEC IG-Sort Mini system automates the handling of remake units. Furthermore, freshly sealed insulating glass units are gently placed in slots, avoiding movement and potential damage.

What advantages does the system offer?

- Automatic ejection of waste insulating glass units and autonomous handling of remakes

- No subsequent completion of glass storage racks in the dispatch department -> reduction of physical effort required of employees

- Cycle time-neutral and automatic intermediate buffering of remakes downstream of the insulating glass line, so that only glass storage racks that are ready for dispatch leave the insulating glass line -> elimination of search times in the dispatch department

- Individually expandable either

- Two insulating glass buffers opposite each other, or

- Two insulating glass buffers arranged one behind the other

- Patented process for handling insulating glass

- Only racks ready for dispatch leave the insulating glass line

- No manual sorting of remakes in dispatch

The Highlights

Modular assembly

The composition of the heights, lengths and numbers of slots can be individually configured according to customer requirements.

High-end solution of a fully automatic buffer system for sealed units

The sorting system functions fully automatically, which ensures the highest quality.

Cycle time gains

The insulating glass buffer ensures continuous output at the insulating glass production line.

- Systems & Lines

- Individual Machines

- Software