Systems & Lines

Logistic systems

- LiSEC

- Systems & Lines

- Logistic systems

- IG-Sort Midi

IG-Sort Midi

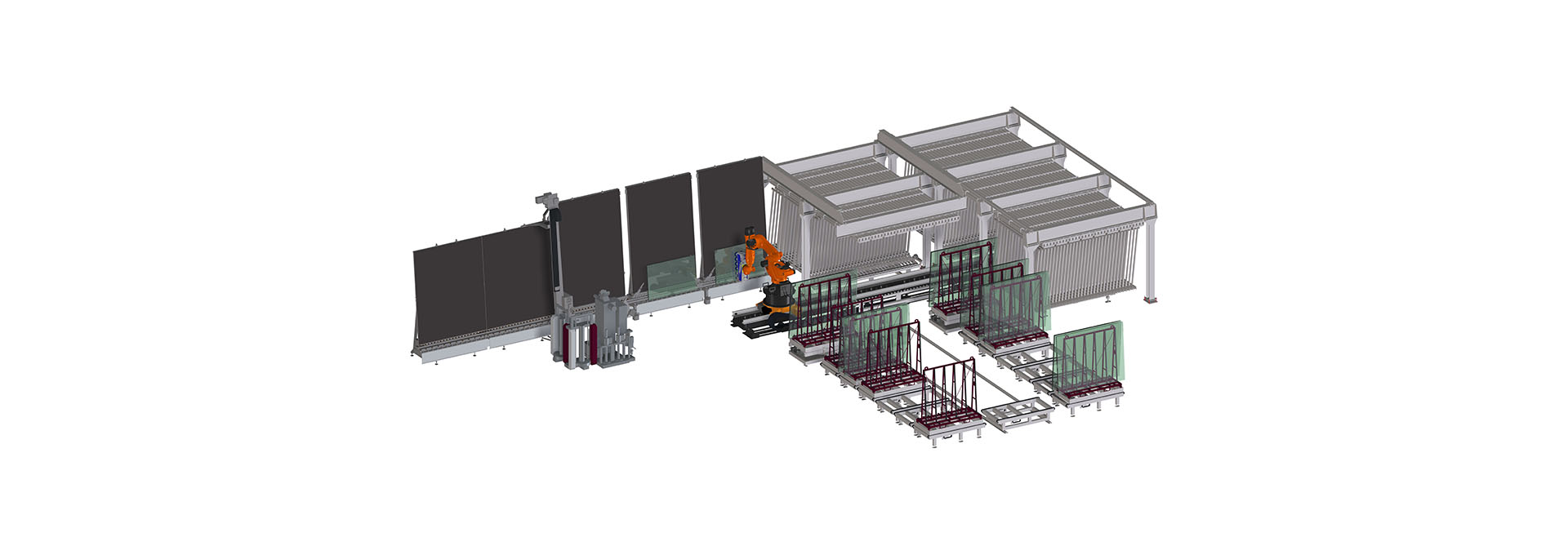

Autonomous insulating glass unit production prioritised

A robot system places insulating glass units on so-called glass storage racks, which are located on a rotating station and can be loaded on both sides. As soon as these racks are fully loaded, their entire load is transported to the so-called A-rack buffer station by means of a shuttle system.

However, if missing or damaged units are detected – either manually or by a scanner system, it is not possible to adhere to the originally planned sequence on the dispatch rack. With the IG-Sort midi, LiSEC offers the perfect solution for precisely this challenge.

What makes it unique:

All of the following insulating glass units in a gap-filled glass rack caused by a broken sheet are placed in a unit buffer. Only once the remake has been produced and placed in the unit store is the incomplete glass storage rack completed in the specified sequence. The LiSEC IGB insulating glass buffer automates the manual handling of remake units on the glass racks. A further innovation is the gentle storage of freshly sealed insulating glass units with thermoplastic spacers in slots, which results in no movement between the unit and the bars or rollers. These units are therefore placed with the utmost care.

What advantages does the system offer?

- Autonomous production for up to 5 hours

- Automatic A-rack infeed and outfeed via shuttle transport

- Can be individually extended either with two opposing insulating glass buffers or two insulating glass buffers arranged one behind the other

- Slots for A-racks

- Automatic ejection of waste insulating glass units and autonomous handling of remakes

- No subsequent completion of glass storage racks in the dispatch department, which leads to a reduction in the physical effort required of employees.

- Cycle time-neutral and automatic intermediate buffering of remakes downstream of the insulating glass line, so that only glass storage racks ready for dispatch leave the insulating glass line and no time is required for searching in the dispatch department

- Patented process for handling insulating glass

- Only racks that are ready for dispatch leave the insulating glass line

- No manual sorting of remakes in dispatch

- Extended version of the insulating glass buffer, with 32 additional glass slots (= extension to "double rack")

The Highlights

Modular assembly

The composition of the heights, lengths and numbers of slots can be individually configured according to customer requirements.

High-end solution of a fully automatic buffer system for sealed units

The sorting system is fully automatic, which ensures the highest quality.

Cycle time gains

The insulating glass buffer ensures continuous output at the insulating glass production line.

- Systems & Lines

- Individual Machines

- Software