Individual Machines

Laminated Glass Production

- LiSEC

- Individual Machines

- Laminated Glass Production

- FTC-C

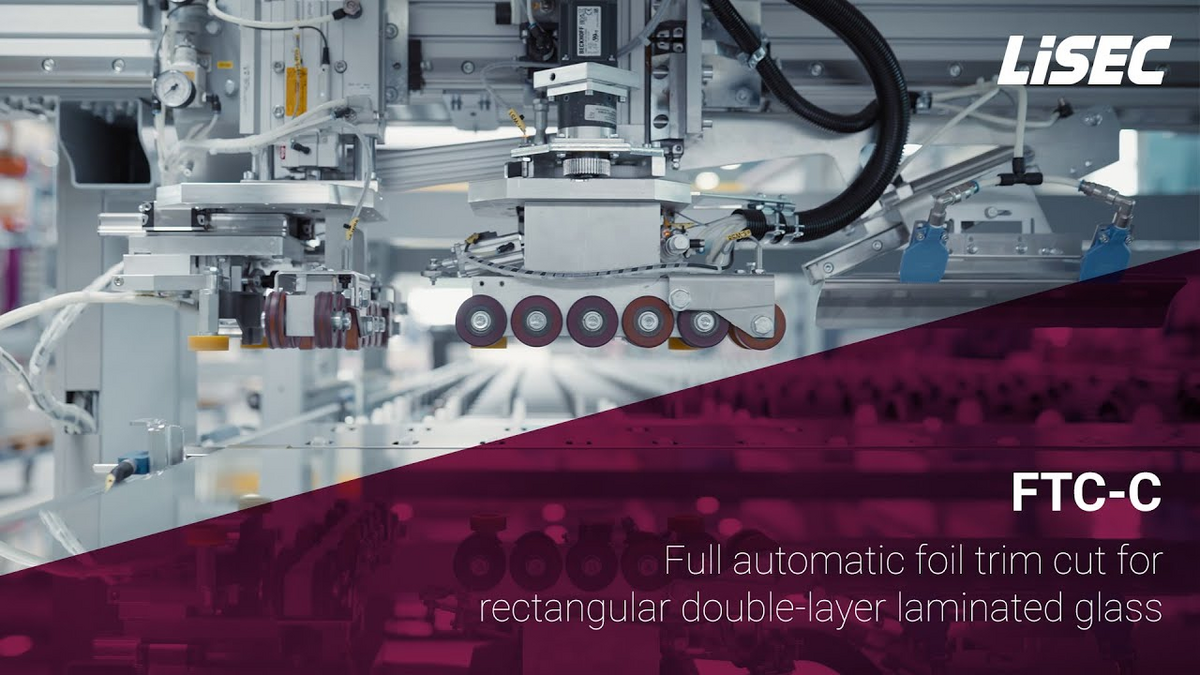

FTC-C

Automatic trimming of the protruding foil on all four sides of a rectangular glass-foil-glass package

The FTC-C from LiSEC automates the cutting of foils in laminated glass production and ensures consistently high quality. The system reduces the risk of injury, saves time and minimises wastage, thereby ensuring more economical and safer production.

How is the LiSEC FTC-C configured?

The FTC-C is a fully automatic stand-alone machine for the precise cutting of foils for rectangular, 2-sheet laminated glass. Two work stations facilitate a high material throughput. The machine processes glass from 600 x 400 mm (L x W) up to 3300 mm wide and up to 12 metres long.

How does the FTC-C work?

The machine handles the cutting of the foil fully automatically. The desired foil protrusion is individually set. The result: precise, clean cuts without manual reworking.

Who is the FTC-C suitable for?

For manufacturers of laminated glass who place value on reproducible quality, higher efficiency and lower error quotas - especially for large glass units.

What advantages does the system offer?

The FTC-C stands out thanks to its fully automatic processing of rectangular 2-sheet laminated glass and ensures high and consistent quality for every sheet. The system offers maximum flexibility thanks to its support for numerous foil types and the option of individually adjusting the foil protrusion (up to 50 mm on the reference, leading and trailing edges and, depending on the glass size, up to 500 mm on the counter-reference side). Two work stations ensure a higher material throughput while simultaneously facilitating the processing of large glass units. This not only reduces the time needed, but also significantly reduces wastage. The automated process also minimises the risk of injury, significantly increasing occupational safety. The FTC-C increases overall efficiency in production and ensures high-quality results - sheet by sheet.

- Fully automatic processing of rectangular glass sheets

- Processing of numerous foil types

- Individually adjustable foil protrusion

- High throughput thanks to two work stations, since assembly and foil trimming are separated

- Reduced risk of injury

- Less wastage and more efficiency

- Perfect quality with every sheet

The Highlights

Automatic glass cutting up to 3300 mm in width

The FTC-C processes rectangular glass lites sheets with a width of up to 3.3 metres fully automatically. This means that very large glass units can be processed efficiently without the need for manual intervention - ideal for modern architectural projects with large glass surfaces.

Precise processing of excess foil

The machine allows an individually adjustable foil protrusion: up to 50 mm on the reference side as well as on the leading and trailing edge, and, depending on the glass size, up to 500 mm on the counter-reference side. This flexibility ensures that different customer requirements and product specifications can be fulfilled without any problems.

Reliable quality with every cut

Automated handling means that the risk of slippage (offset sheets), bubble formation in the edge area due to excessive cutting back of the foil or contamination of the laminate is significantly reduced. The uniform precision ensures consistently high product quality, irrespective of the operating personnel or shift.

- Systems & Lines

- Individual Machines

- Software