Systems & Lines

Logistic systems

- LiSEC

- Systems & Lines

- Logistic systems

- Buffer and sorting system – stationary

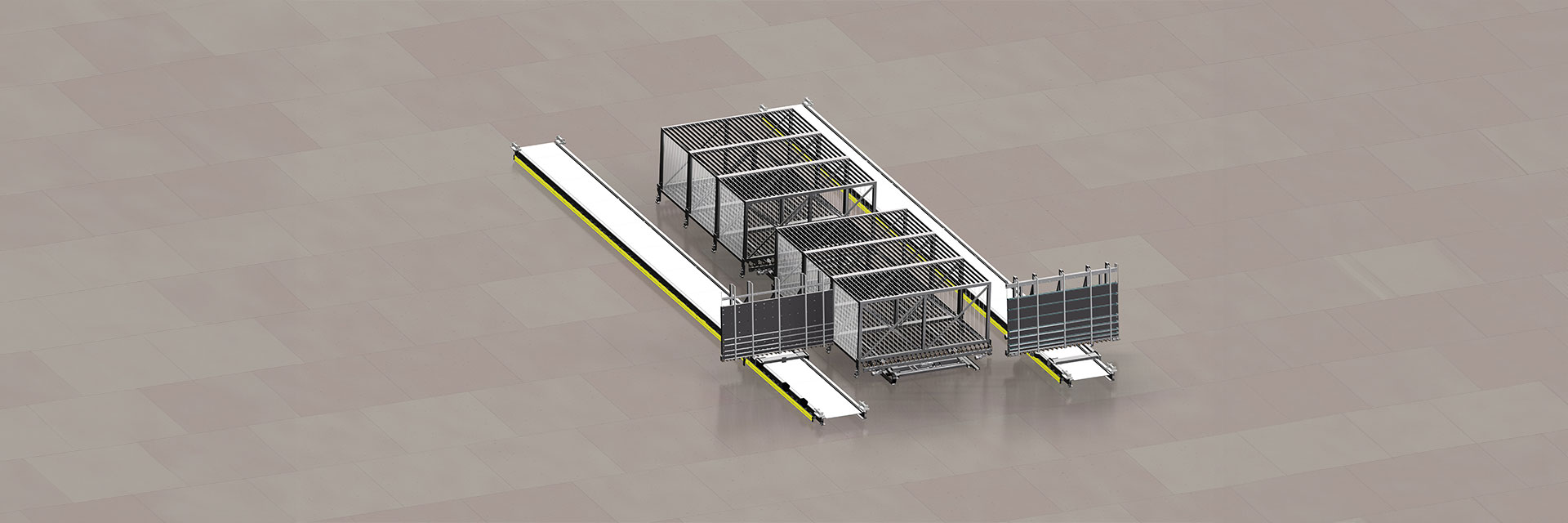

Buffer and sorting system – stationary

... a central component of intralogistics

As a key element for planning an optimum production process, the buffer and sorting system makes it possible to decouple key processing steps in the value chain and also ensures exten-sive process stability and optimised machine utilisation.

What is the layout of a stationary LiSEC buffer and sorting system?

A stationary buffer and sorting system essentially consists of:

• Transport shuttle (SHL)

• A sorting magazine (ASM) to be equipped according to customer requirements

Depending on the position within the production process for which this system is used, there are two options for its application:

A) Feeding of production lines (= positioning of the system before the production process)

B) Feeding of the ASM from upstream production lines with glass sheets that are to be sorted, buffered and transported out again at a later time for further processing (= positioning of the system after or within one or more processing steps).

How does a stationary LiSEC buffer and sorting system work?

Transport shuttle – SHL

The cycle time-optimised movement of the shuttle carriage (glass sheets are transported to the end of the shuttle transport carriage during the process) ensures extremely rapid cycle times with simultaneous contactless transport of the coating side.

Furthermore, the use of low-maintenance and standardised components guarantees a mainte-nance-friendly and easily expandable system.

Sorting magazine – ASM

The LiSEC sorting magazine offers the following:

• Suitable for equipping with up to 6 modules

• High module variance – each module can be equipped according to customer require-ments (different glass thicknesses, heights, lengths and numbers of compartments)

• Multiple loading of slots is possible according to glass sheet size

The fully automatic transfer and further processing of glass sheets, which are transported in a random sequence and size from upstream vertical systems, also pose no problem for this sys-tem.

Who is a stationary LiSEC buffer and sorting system suitable for?

The implementation of this system is ideal for existing operations with tight spatial conditions as well as for green field projects that want to invest in a highly automated buffer or sorting system.

Furthermore, the use of our buffer and sorting system is recommended for companies that want to avoid incorrect loading, ensure the traceability of the sheets, prevent disruptions on the production lines and instead achieve more performance with enhanced quality.

What are the advantages of a stationary LiSEC buffer and sorting system?

The high degree of automation of this solution renders manual intervention virtually superflu-ous and also brings other advantages:

• Only the uncoated side of a coated glass sheet is touched; the coating remains undam-aged

• An inclination angle of approx. 2° during transport of the glass sheet serves to protect the coating

• There is no impairment of the edge quality of a glass sheet

• High system availability – can be used 24/7 in a highly automated manner with low maintenance requirements.

• Ensures extensive process stability

• Guaranteed supply reliability for the respective processing steps – even with different sheets.

• Use of high-quality guide rails that are protected against glass particles, enabling a ser-vice life of approx. 1.6 million kilometres to be achieved.

Highlights / other benefits as bonus features

• Optimised cycle time – glass sheets are transported to the end of the shuttle transport carriage during travel.

• Maintenance-friendly – automatic lubrication system, low-maintenance components, easily replaceable wearing parts

• Standardised LiSEC rail system – expandable without difficulty, can be combined with tilting shuttle or fixed transport shuttle

What functions are included as standard?

• Automatic lubrication system

• Data transfer: By means of reliable, optical data couplers

• Use of our standardised LiSEC rail system – expandable without difficulty, can be com-bined with tilting shuttle or fixed transport shuttle

Technical Data

| Technical product specification | Unit | ASM | SHL | SHL-VH | SHL-V |

|---|---|---|---|---|---|

| Angle of inclination | ° | 2 | 2-8 | 2-90 | 6 |

| Transport heigt | mm | 520 | 520 | 520 | 520 |

| Max. length | dm | 60 | 60 | 50 | 45 |

| Max. height | dm | 33 | 33 | 27 | 25 |

| Min. size | mm | 350x180 | 350x180 | 350x180 | 350x180 |

| Min./max. workpiece thickness | mm | 2.3-25 | 2.3-25 | 2.3-25 | 2.3-25 |

| Max. load | kg | 156 kg/lfm | 150 kg/lfm | 150 kg/lfm | 74 kg/lfm |

| Glass transport speed up to | m/min | 60 | 60 | 60 | 60 |

| Driving speed up to | m/min | 100-150 | 300 | 300 | 75 |

| Number of slots | mm | 32-85 |

- Optimised cycle time – glass sheets are transported to the end of the shuttle transport carriage during travel.

- Maintenance-friendly – automatic lubrication system, low-maintenance components, easily replaceable wearing parts

- Standardised LiSEC rail system – expandable without difficulty, can be combined with tilting shuttle or fixed transport shuttle

- Equipment for processing shapes per the LiSEC shape catalogue

- Glass thicknesses of up to 25 mm

- Systems & Lines

- Individual Machines

- Software