Individual Machines

Thermoplastic Spacer

- LiSEC

- Individual Machines

- Thermoplastic Spacer

- TPA

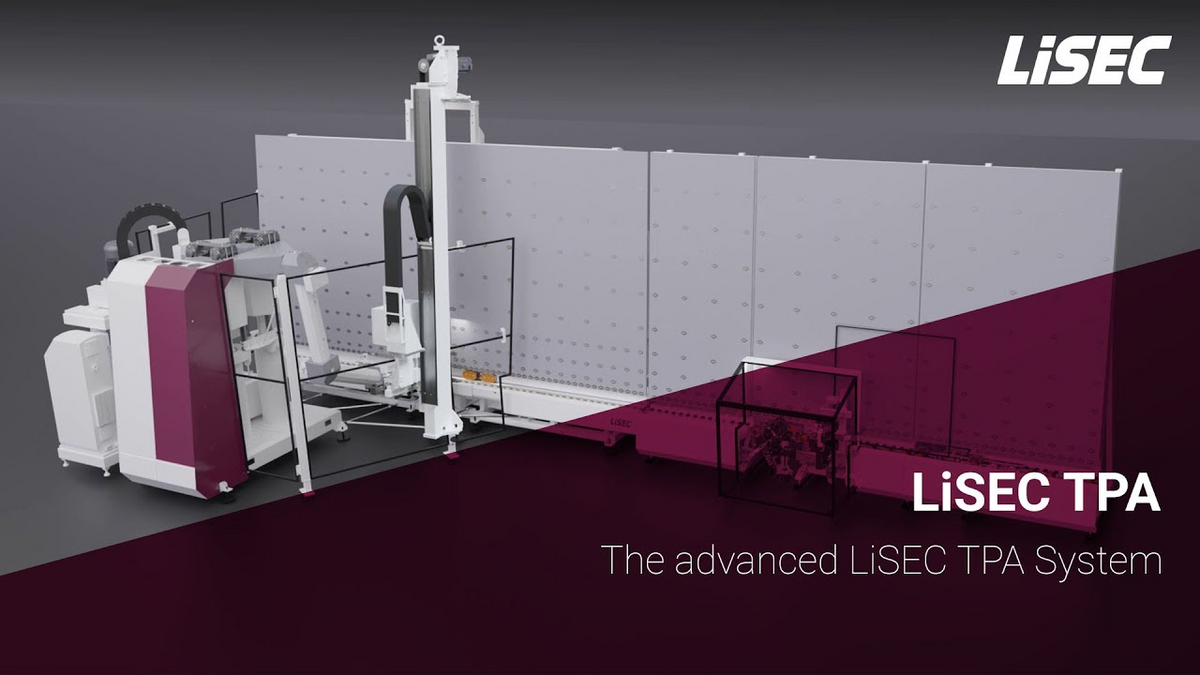

TPA

Automatic processing of thermoplastic spacer bars

The LiSEC TPA is a fully automatic system for applying thermoplastic spacer bars. It allows the highest flexibility by seamlessly switching between different dimensions of the glass. The stepless width adjustment allows switching between different spacer widths without the requirement for a waiting time.

How is the TPA configured?

The TPA consists of a drum melting pump (DMS-200), two intermediate tanks, a controlled hydraulic system and a flow control valve.

How does the automatic processing of thermoplastic spacers work?

The drum melting pump (DMS-200) heats the material and conveys it from the 200l drum into two intermediate tanks. These each have a volume of 20l and ensure uninterrupted operation of the TPA due to the alternating mode of operation.

The material is metered by means of a controlled hydraulic system and a flow control valve. The volumetric measuring system directly in front of the application nozzle applies exactly the right amount of material and compensates for fluctuations in the material batch and temperature.

New and improved metering technology ensures highly precise and reliable application. Furthermore, the process steps of assembly and pressing have been adapted to the special requirements of the thermoplastic material. The use of a special calibration station prevents overpressure in the unit and therefore supports the adhesion of the TPA material.

Who is the TPA suitable for?

The TPA is the solution for the modern insulating glass line. The thermoplastic spacer system provides a warm edge in the insulating glass due to its high thermal insulation. Operation of the insulating glass line is greatly simplified by eliminating conventional frame production. Rather than requiring numerous consumables such as bar material, desiccant and butyl, the system only requires the thermoplastic material in the form of a drum. The high flexibility of the system enables a batch size of 1 and therefore ensures maximum productivity in insulating glass production.

What advantages does the TPA offer?

With the LiSEC line concept, the assembly, gas filling, and pressing process steps satisfy the special thermoplastic spacer bar requirements. The permanent support of all glass lites sheets ensures the smallest tolerances in the unit thickness and in the positioning of the glass lites sheets in relation to each other. The line principle also applies to the logistics aspects. This makes it possible to consistently ensure the quality produced during application.

- Measurement of the glass thickness and compensation of the glass tolerances with an applicator (precise unit thickness)

- Automatic quantity correction through active quantity measurement

- Precise application due to CNC-controlled axis systems

- Low-wear conveyor technology from the 200l drum into the 20l material buffer

- Seamless and tight connection of start and stop of the thermoplastic spacer

- Archiving of the captured images for the join including image database of the corners and joining parts

- Optimised ISO line to the requirements of the TPA (summarised):

- Precise unit thickness

- Pressure-free assembly

- Permanent support of all glass lites sheets of the unit

The Highlights

Improved metering technology ensures highly precise and reliable application

Highly accurate metering of the material ensures continuous application of the spacer at the correct height and width. This ensures optimum adhesion of the material to the glass and therefore also a long unit service life. The servo-controlled positioning system enables precise alignment of the glass and ensures the lowest tolerances at the insets.

Durable and aesthetic join with high process reliability

The application of thermoplastic spacer material enables a join that is barely visible when installed. It also ensures that the spacer is absolutely gas-tight. The spacer material is pressed carefully into a moulding chamber at the sealing position. The result is unique and cannot be compared with conventional solutions in terms of the appearance and process reliability.

Uninterrupted production thanks to infinitely variable width adjustment of the applicator nozzle and an alternating material buffer

A change in the width of the spacer takes place without the need for a waiting time due to the stepless nozzle adjustment. Thanks to the intelligent intermediate buffer up to 40l of material are available when changing the drum, meaning that production can be continued at this time. This results in a large time window during which the drum can be changed and then reheated.

- Systems & Lines

- Individual Machines

- Software