Individual Machines

Pressing

- LiSEC

- Individual Machines

- Pressing

- FPS-A

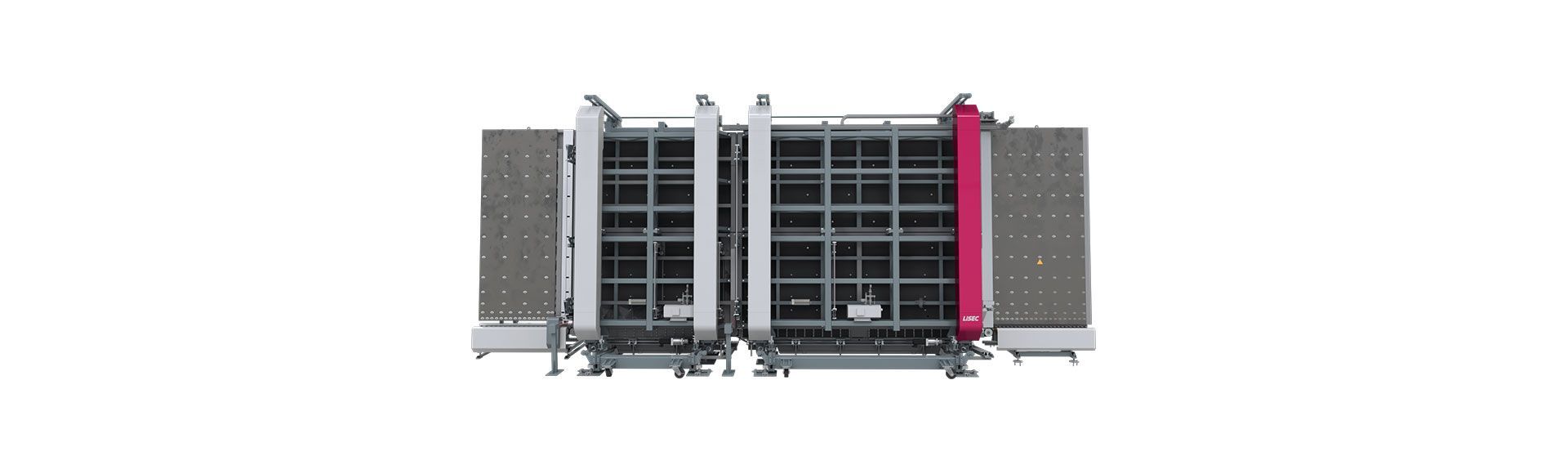

FPS-A

Universal gas filling press for fully automatic gas filling, assembly and pressing of insulating glass units

The latest generation of gas filling presses is suitable for a wide range of applications thanks to the individual configuration possibilities and impresses with an excellent price/performance ratio. The improved transport system takes all glass types into account during assembly allowing the processing of thermoplastic spacers as well.

How is the FPS-A configured?

Glass transport is implemented via a divided carrier with toothed belt. The reinforced design makes it possible to process high glass thicknesses and heavy units. The pressed panel surfaces are made of special multi-layer panels, which guarantee precise package thickness of the insulating glass unit with the lowest manufacturing tolerances.

The waterproofing of the pressing chamber is achieved on the inlet side by means of a fixed seal bar and on the outlet side by means of a moveable seal bar, so that the gas consumption is minimised.

How does the fully automatic gas filling press work?

The first glass sheet is transported in and is positioned in the press after the trailing edge has been detected by a sensor. The vacuum suction cups on the opposite moveable press plate adopt the glass sheet. The second glass sheet equipped with its spacer bars is transported in and placed in the same position as the previous glass sheet. The press chamber is then made waterproofed. In the newly formed cell, the gas rises inside the unit and displaces the enclosed air upwards without producing any turbulence. Once the required gas amount has been attained, the unit is pressed and sent out.

Who is FPS-A suitable for?

Its universal application possibilities mean that the FPS-A can be used both for the cycle-time-optimised production of windows and doors as well as for the manufacture of heavy façade elements.

The use of high-quality components means that maximum system availability is guaranteed and operating and maintenance costs are reduced to a minimum.

What advantages does the FPS-A offer?

The FPS-A is perfectly suited for the production of double, triple and multiple insulating glass units. The new transport system supports all glasses of the unit, which makes the processing of thermoplastic spacers as well as heavy insulating glass units effortless.

Optimising the step mechanism now allows a bottom edge step of up to 150 mm to be produced. As a result, particularly heavy sheets can also be processed.

- Processing of rigid, flexible as well as thermoplastic spacers

- Unit thickness 10 - 100 mm

- Unit weight of up to 350 kg/m

- 3-side steps 0 - 1000 mm, step at lower edge up to 150 mm

- A specially developed nozzle system ensures turbulence-free gas filling of insulating glass units with the highest filling degree value

- Optimum dimensional accuracy (+/- 0.5 mm)

- Applicable for quadruple units

The Highlights

Movable seal bar

The movable seal bar adapts to the unit size and therefore ensures a very high filling level with only a small amount of wasted gas in the process.

Flexible press plate surface

The flexible surface compensates for any unevenness in the glass surface and therefore reduces the risk of glass breakage. It also ensures a very high level of accuracy.

Production of stepped units

The innovative fixture for the production of stepped units allows steps in the range of the lower edge from 0 - 150 mm.

Split belt drive

The newly developed split belt drive ensures permanent support of the unit.

- Systems & Lines

- Individual Machines

- Software