Individual Machines

Sealing

- LiSEC

- Individual Machines

- Sealing

- SRP-A

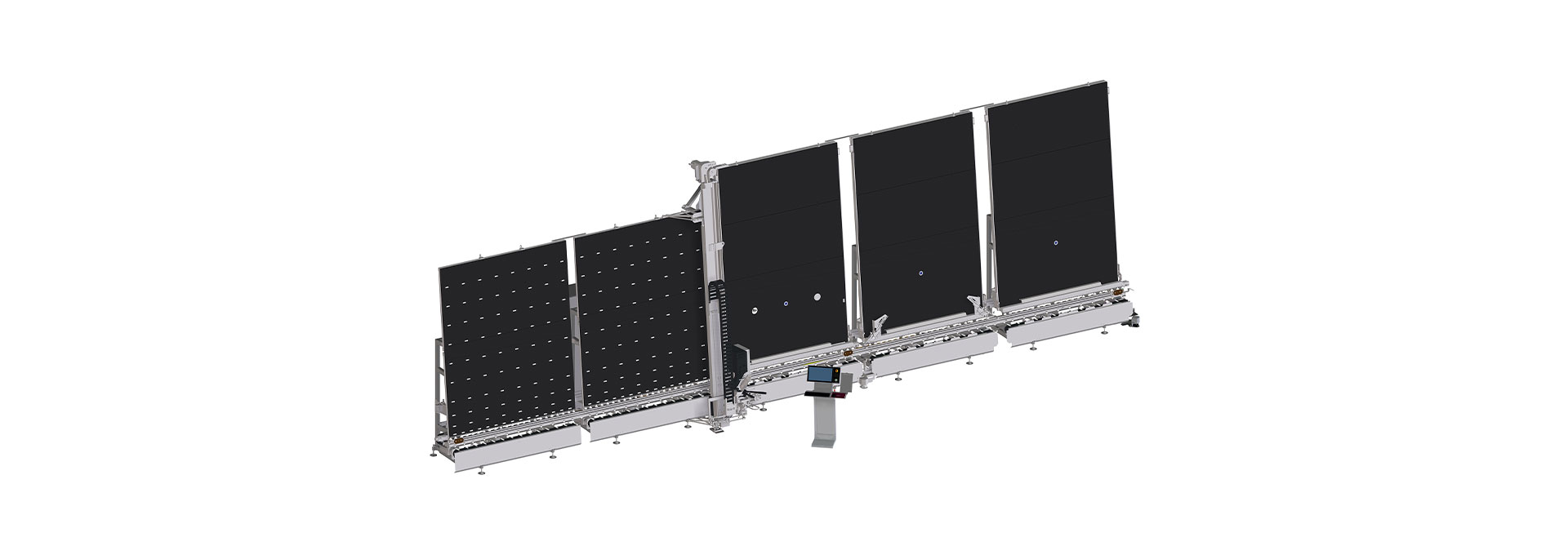

SRP-A

Fully automatic system for sealing insulating glass units

The LiSEC SRP-A is a system for sealing insulating glass units with two-component sealants. The sophisticated build-up of this system guarantees maximum process reliability and quality, even with heavy units.

How is the SRP-A configured?

The SRP-A consists of a modular system comprising several transport sections and a vertical sealing bar. Glass is transported via an innovative “full-support belt system” that provides optimum support for the unit. The integrated cleaning system ensures that the support jaws remain clean by means of scraper units and a rotating brush.

From the outlet zone, an additional horizontal roller beam with a defined distance to the back wall guides the unit at the upper edge. This facilitates inspection and removal of the sealed units.

How does the automatic sealing of insulating glass units work?

The insulating glass unit is held by dynamically moving suction slides to ensure controlled transport along the system. The thickness and build-up of the unit are measured in the separate upstream measuring section. The required material quantity is determined together with the value from the depth measuring device.

The material is conveyed via a precise cylinder extrusion system and applied by means of a rotating application head. In the final step, automatic corner correction is performed to ensure fast and high-quality sealing results.

Who is the SRP-A suitable for?

The innovative and fully automatic sealing machine ensures unbeatable quality when sealing insulating glass units. Thanks to its extremely stable design, the system can also handle heavy façade units without difficulty. The use of numerous high-quality components facilitates maximum system availability and reduces operating and maintenance costs. As such, the SRP-A is an asset for every insulating glass manufacturer.

What advantages does the SRP-A offer?

The SRP-A is ideally suited for the production of double, triple and quadruple units. With its high sealing speed, the system is ideal for the rapid production of window and door units, as well as for the manufacture of complex façade units.

The replaceable support jaws and easy-to-clean conveyor belts keep maintenance costs to a minimum.

The material feed and application head are clearly arranged, allowing easy access for changing nozzles and performing maintenance tasks.

It is possible to ensure the rapid production of large insulating glass units thanks to uninterrupted material dosing. The maximum configuration is capable of processing up to three different sealants, meaning that the SRP-A satisfies every requirement for the production of façade units.

- Continuously circulating application with perfect corner formation

- CleanSeal technology: Dynamic precision dosing system

- Full-support belt system for optimum unit support

- Effortless removal of finished units thanks to the use of optional lifting devices with support at the lower edge

- High cycle frequency due to removal section included as standard, which uncouples the unloading process from the sealing process

The Highlights

Optimised suction axis system for guiding the insulating glass with high stability

Due to the reduced contact area between the transport system and the insulating glass unit, continuous guidance by means of suction cups is essential for reliable processing.

Precision dosing system with quantity and speed control

Quantity and speed are controlled fully automatically by an innovative precision dosing system. This facilitates high-quality sealing of the units.

Integrated cleaning equipment ensures constant cleanliness and reduces the amount of manual cleaning required

A scraper device in the area of the sealing head enables automatic cleaning of the nozzle surface. The brush system below the conveyor belt performs dry cleaning of the individual support jaws, thereby reducing the amount of manual work required.

- Systems & Lines

- Individual Machines

- Software