Individual Machines

Laminated Glass Cutting

- LiSEC

- Individual Machines

- Flat Glass Cutting

- VSL-A

VSL-A

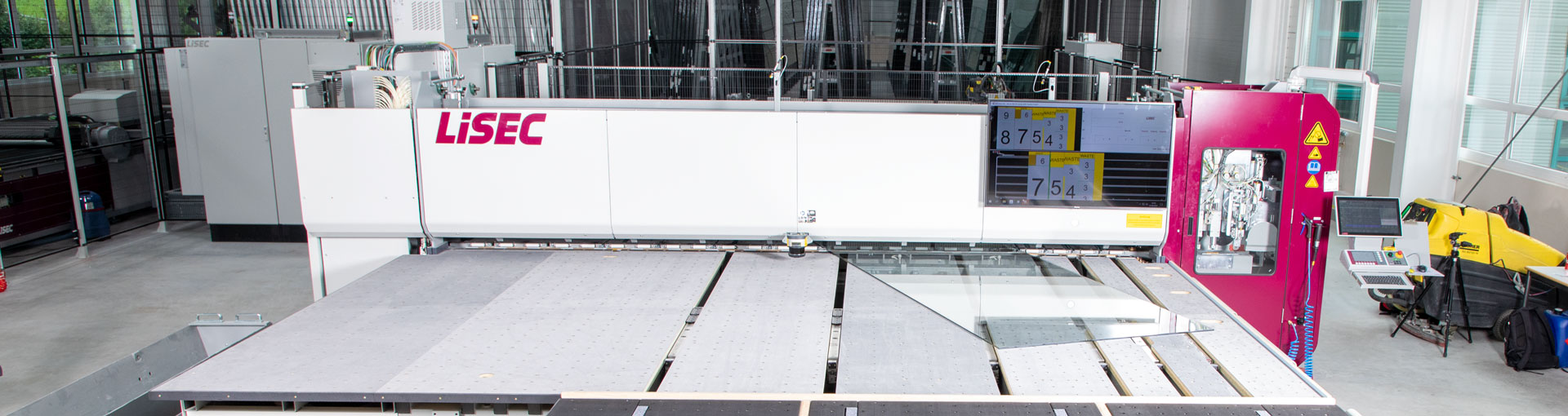

High performance automatic cutting machine for laminated glass

The automatic cutting system of the VSL-A series combines state-of-the-art laminated glass cutting technology with decades of LiSEC know-how in automatic laminated glass processing.

How is the laminated glass cutting system configured?

After loading the system, a transport section follows that forms the transition to the new VSL-A laminated glass cutting system

How does the laminated glass processing work?

The edge deletion of coated laminated glass takes place optionally with the upstream float glass cutting, or directly at the laminated glass cutting bridge. The raw glass sheet is subsequently positioned at the laminated glass cutting bridge limit stops, automatically aligned and cut. The sub-plates are turned with rotary vacuum suction cups, which makes fully automatic processing possible. Conveyor belts automatically transport the cut sheets into the acceptance area. Here, the sheets can be removed manually or with tilt arms. The remnant glass lites are either transferred to the integrated remnant glass lite disposal section, or into the optionally available remnant plate storage.

For whom is the laminated glass cutting system suitable?

Both small glass processing companies and large companies benefit. A perfect glass edge can now be produced easier, quicker and more economically than ever before. This system adapts to given requirements, provides automatic support and can be expanded as required.

What advantages does the machine offer?

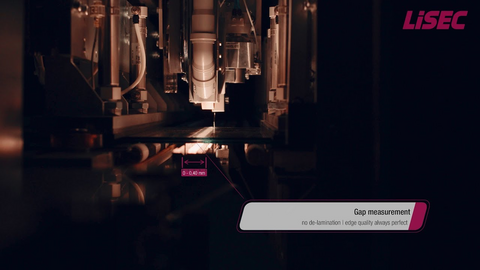

The system guarantees up to 10% better cutting quality than comparable systems on the market, thanks to the patented SIR infra-red radiator and hot cutting process with continuous gap measurement. Thanks to the new clamping bar technology, edge and off-cuts of up to 200mm are possible fully automatically, which on the one hand enables more efficient sheet optimisation and on the other hand drastically saves costs. On average, 6% glass consumption can be saved by the VSL-A. Depending on the optimisation, up to 30% higher cutting capacities are possible. Automatic rotation of the sub-plates is part of the standard equipment, as is automatic residual cut disposal, and reduces operator intervention to a minimum. Just like the proven electronic aids such as cutting wheel blades and cutting oil monitoring.

What functions are included as standard?

- Processing glass thicknesses from 2.2.1 to 10.10.12

- Trim cutting of 20 mm on all four sides of the raw glass sheet

- Automatic off-cut disposal up to 300mm

- Processing of X/Y and Z cuts without any operator intervention through the automatic turning of the sub-plates with 2-point rotary suction cup

- Newly developed and patented SIR - Infra-red Power Heating (foil heating) in segmented design

- Cutting of shapes without arches with laser-assisted manual positioning

- Automatic outfeed of the cut sheets into the acceptance area

- Lateral unloading rollers for simple sheet unloading that protects the back

- Intuitive operation with touchscreen on a tilt arm directly on the system

What functions are optionally available?

- Processing of glass thicknesses up to 12.12.12

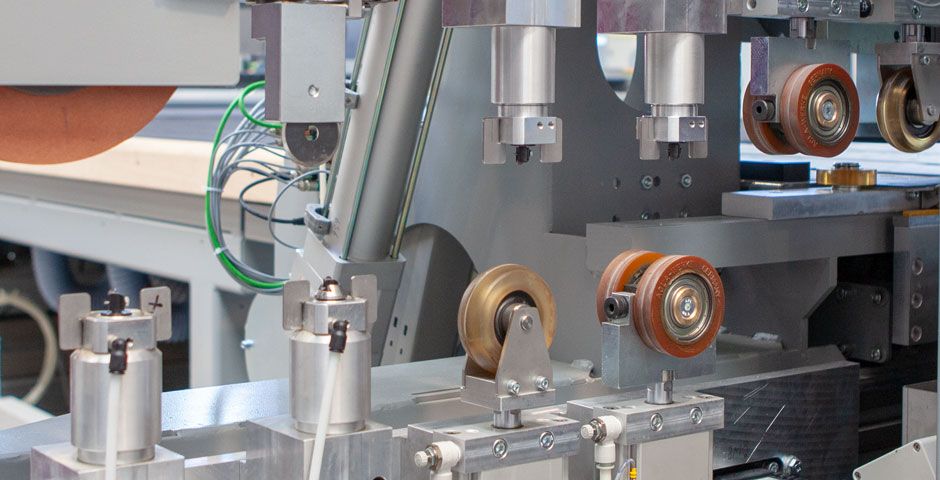

- Two cutting heads with automatic cutting wheel change

- Processing of W cuts without any operator intervention through the automatic turning of the sub-plates with 2-point rotary suction cup

- Fully automatic cutting of shapes with laminated glass

- Extending tilt arms for unloading large and heavy sheets

- Additional cutting head, which enables an automatic tool change with different glass thicknesses

- Removal of the Low-E coating with a grinding wheel on the laminated glass cutting bridge

- Innovative retaining beam technology for higher output

- Automatic turning of sub-plates

- Constantly perfect alignment guarantees extreme precision

- Two cutting heads enable automatic tool changes

The Highlights

Innovative retaining beam technology for higher output

The clamping bar technology leads to a reduction in the cutting times, which also reduces the cycle times - and by up to 30%. As such, it is possible to efficiently satisfy the increasing requirement for laminated glass with just one cutting bridge. Thanks to the integrated Low-E mode, relative movements on the glass surface are prevented, which maximises the glass quality.

Automatic turning of sub-plates

Two rotating vacuum suction cups grip the raw glass sheet from below. Through the servo coupling of both axes, the sheet is turned through precisely 90° and accurately aligned with the limit stops fully automatically. Operator intervention is no longer necessary and the fully automatic processing of X, Y and Z cuts is guaranteed.

Always perfectly aligned and therefore extremely precise

The five mobile positioning stops are retractable in the positioning station and ensure exact alignment of the glass sheets. The limit stops are equipped with a clamping function for the automatic outfeed of off-cuts. Vacuum suction cups on the top side transport the glass sheets into the acceptance area, or serve as positioning aids during cuts that are longer than the positioning station.

Two cutting heads enable automatic tool changes

Through the optional equipment of the system with two cutting heads, it is possible to use different cutting wheels. With this option, the system changes to the correct cutting wheel with a change in glass thickness, and therefore reduces standstill times and errors. The cutting heads can be optionally equipped with identical cutting wheels for series production. In this case, the system changes a worn cutting wheel for the unused one, therefore also avoiding times at a standstill and erroneous breaks.

- Systems & Lines

- Individual Machines

- Software