Software

Data Insight

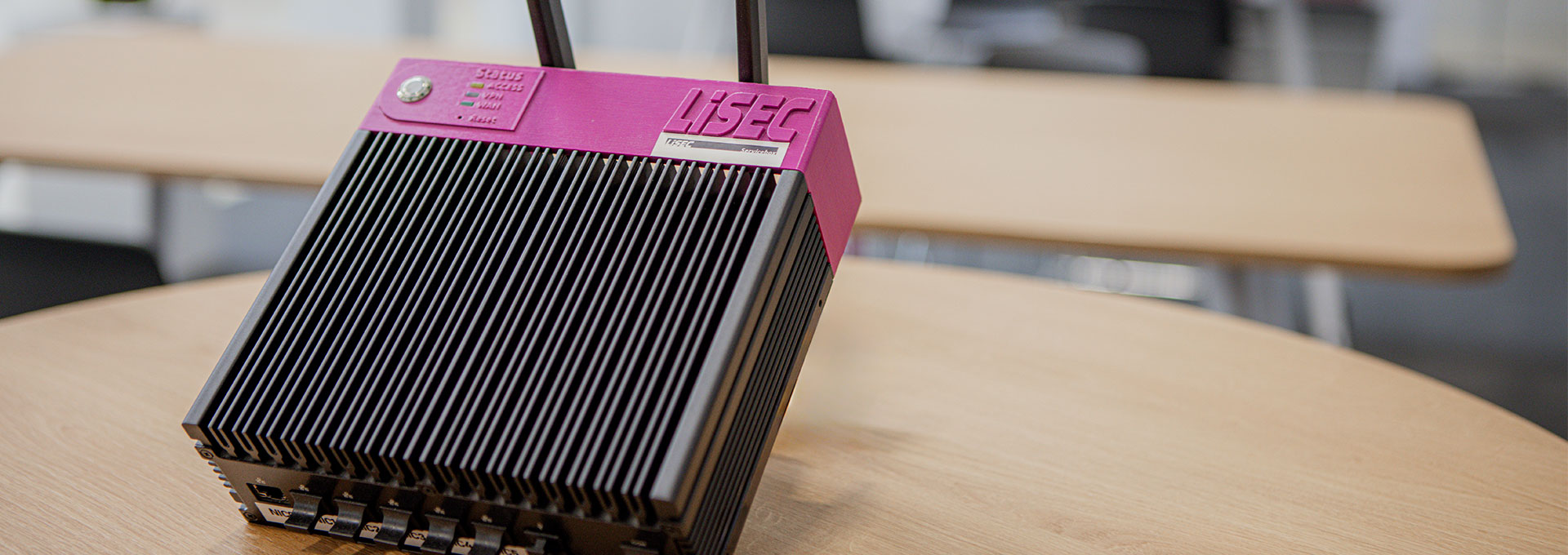

lis.edgebox

Safe and secure remote maintenance and data acquisition

Performing safe, secure and regular maintenance of production facilities is a challenge in the flat glass industry, while it is also essential to record and analyse the data generated in the production environment in order to optimise processes and increase efficiency. This requires secure and reliable solutions that guarantee remote maintenance, as well as data acquisition and transfer to the cloud.

How is lis.edgebox structured?

lis.edgebox consists of a device and a global technical management network that is developed and operated through collaboration between an Austrian provider of security solutions and LiSEC. The device is installed in the customer's network and managed and maintained by LiSEC technicians. There are two variants: a physical device based on an industrial PC and suitable for installation on the shop floor, and a virtual version that can be installed in the customer's virtual environment (e.g. VMWare, Hyper-V).

How does lis.edgebox work?

lis.edgebox fulfils two central functions: secure remote maintenance of industrial plants and production-related systems and the collection and secure transmission of production data to the Microsoft Azure Cloud. For remote maintenance, the device establishes a VPN connection to the nearest hub system in the management network. This connection enables technicians to perform remote maintenance. The customer can activate or deactivate the VPN tunnel at any time, and therefore retains full control over whether remote maintenance is possible. Furthermore, the device offers a web front end that gives the customer access to a log of all past remote maintenance activities and allows them to see when and whether remote maintenance was carried out.

For the purpose of data acquisition, the device operates various containers that collect, filter and aggregate production data from machines and production-related systems before transmitting it securely to the Microsoft Azure Cloud. This takes place using the Azure IoT Edge Runtime from Microsoft. The collected data forms the basis for other software solutions such as lis.analytics and lis.qualitypass.

Who is lis.edgebox suitable for?

lis.edgebox is suitable for all companies in the flat glass industry that use machines or software from LiSEC, and that value secure and reliable remote maintenance, as well as those that also want to use data generated in production in order to make decisions on this basis.

What advantages does the software offer?

lis.edgebox offers numerous advantages, including:

- Secure and reliable remote maintenance that can be activated and deactivated by the customer

- Management by LiSEC so that security and other software updates are installed on the device quickly and reliably

- Stable data acquisition and transmission to the Microsoft Azure cloud

- Physical and virtual implementation for the best possible integration into the existing IT environment

What functions are included as standard?

The standard features of lis.edgebox include:

- Option of activating and deactivating remote maintenance

- Web front end for the traceability of past remote maintenance activities

lis.edgebox is available immediately. Please contact us for further information.

- Systems & Lines

- Individual Machines

- Software